Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Build a Metal Frame Building: A Step-by-Step Guide for Beginners

In recent years, the construction industry has seen a significant shift towards the use of metal frame buildings due to their durability, versatility, and cost-effectiveness. According to a report by the American Institute of Steel Construction, steel frames have become a popular choice for a variety of applications, including commercial, industrial, and residential structures. The global market for metal frame buildings is projected to reach $144.3 billion by 2025, highlighting the increasing demand for sustainable and resilient building solutions.

Building a metal frame structure not only provides a strong foundation but also contributes to energy efficiency and environmental sustainability. As the construction industry focuses more on reducing its carbon footprint, opting for metal frames allows builders to utilize recyclable materials while ensuring a longer lifespan for their buildings. This shift signifies a growing recognition of the advantages that metal frame buildings offer, making the understanding of their construction process essential for both novice builders and seasoned professionals.

In this step-by-step guide, we will explore the fundamentals of building a metal frame building, breaking down the complexities of the construction process into manageable stages. By leveraging industry data and best practices, this introduction aims to empower beginners with the knowledge necessary to embark on their own metal frame construction projects.

Understanding the Basics of Metal Frame Building Construction

Understanding the basics of metal frame building construction is essential for anyone looking to embark on this project. Metal frame buildings primarily consist of steel or metal columns, beams, and bracing, which provide structural integrity and durability. The unique properties of metal, such as its resistance to pests and rot, make it an attractive option for various construction applications, including residential, commercial, and industrial purposes.

Before starting the construction process, it’s important to familiarize yourself with key concepts such as load-bearing capacity, insulation, and the types of metal fasteners used in assembly. A strong understanding of structural engineering principles is crucial, particularly when determining the spacing of frames to ensure they can support the building's weight and withstand environmental forces. Additionally, safety regulations and local building codes should be reviewed to ensure compliance throughout the construction process.

When planning a metal frame building, selecting the appropriate materials and tools is equally important. Various types of metal can be utilized, such as cold-formed steel for structural framing or galvanized steel for enhanced weather resistance. Furthermore, understanding basic construction techniques, including welding, bolting, and anchoring, will help you create a sturdy and long-lasting structure. Overall, mastering these fundamentals will set a solid foundation for any beginner looking to build a metal frame building successfully.

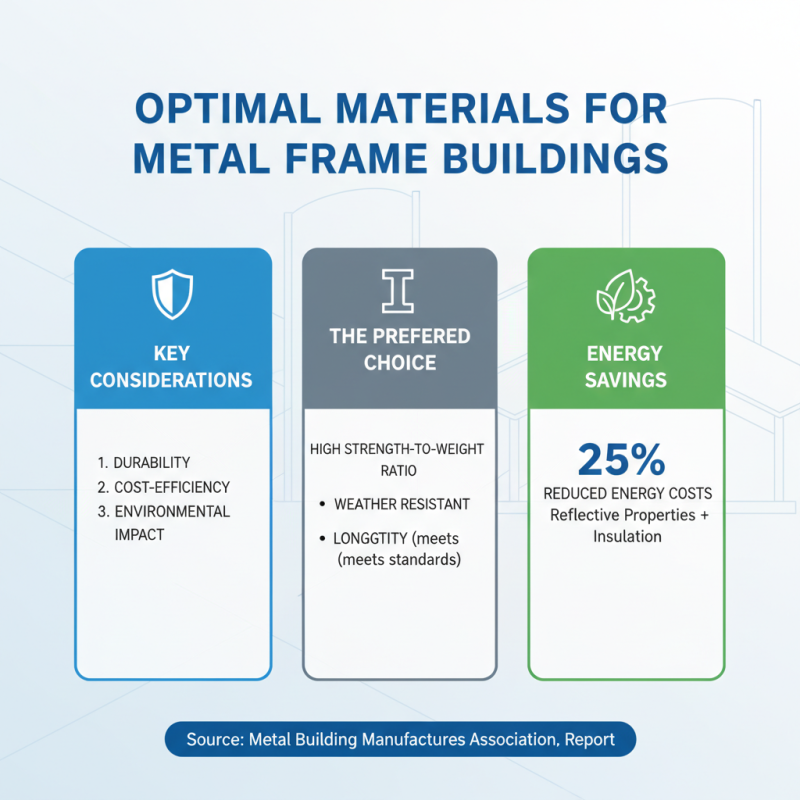

Selecting the Right Materials for Your Metal Frame Structure

When selecting materials for your metal frame building, it's crucial to consider factors such as durability, cost-efficiency, and environmental impact. According to a report by the Metal Building Manufacturers Association, metal structures can reduce energy costs by up to 25% due to their reflective properties and the ability to incorporate insulation effectively. Steel is the most popular choice, known for its high strength-to-weight ratio and resistance to weather elements. It's essential to choose quality steel that meets specified standards to ensure the longevity of your building.

Tips: Always check for certifications related to fire resistance and corrosion resistance when purchasing steel. This can significantly enhance the building's lifespan and reduce maintenance costs over time.

Additionally, consider using recycled steel, which can be both cost-effective and environmentally friendly. Around 70% of steel in the U.S. is made from recycled materials, leading to less landfill waste and reduced energy consumption during production. This shift not only supports sustainable building practices but can also impact your overall project budget positively, making recycled steel an appealing option.

Tips: Explore local suppliers that offer recycled materials, as this can lower transportation costs and support the local economy while ensuring your building adheres to sustainable practices.

Step-by-Step Guide to Designing Your Metal Frame Building

Designing a metal frame building involves several key considerations that can greatly influence the final structure's efficiency and functionality. According to a recent industry report published by the Metal Building Manufacturers Association, the use of metal in construction has been increasing due to its durability, low maintenance costs, and energy efficiency. In fact, energy-efficient designs can reduce operational costs by up to 30%, making metal frame buildings a popular choice for both residential and commercial projects.

When starting the design process, it's essential to assess the intended use of the building. This includes determining the layout, size, and functionality required for your specific needs. For example, a warehouse design may prioritize wide-open spaces and high ceilings for storage, while an office building might focus on maximizing natural light and creating a welcoming environment. Furthermore, industry data highlights that optimized design can lead to faster construction times, with metal buildings being erected 30% quicker on average compared to traditional construction methods.

Additionally, integrating sustainable practices in the design can enhance the building’s appeal and longevity. Modern design approaches often incorporate features such as insulated panels, solar reflective coatings, and rainwater harvesting systems. A study from the American Institute of Steel Construction shows that buildings designed with sustainable principles not only align with market demands for eco-friendly options but also significantly enhance property value. Thus, thorough pre-design planning is crucial to ensure that the construction meets both functional and environmental standards.

Essential Tools and Equipment for Metal Frame Construction

When embarking on a metal frame construction project, having the right tools and equipment is paramount to ensuring efficiency and quality. A report from the Metal Building Manufacturers Association (MBMA) states that nearly 48% of construction delays can be attributed to inadequately planned tool and equipment procurement. Therefore, beginners must familiarize themselves with the essential tools such as welding machines, metal cutting saws, and lifting equipment. Each of these tools plays a crucial role in the overall construction process—from accurately cutting metal panels to securely joining them.

Moreover, protective gear cannot be overlooked. The Occupational Safety and Health Administration (OSHA) emphasizes that proper personal protective equipment (PPE), including safety glasses and gloves, significantly reduces injury risks on construction sites. Additionally, hoisting equipment such as cranes or lifts ensures safe handling of heavy metal components, often found in larger builds. According to industry statistics, effective use of lifting equipment can decrease the risk of accidents related to manual handling by up to 30%. Familiarizing yourself with these tools not only enhances safety but also lays the foundation for successful project execution.

Best Practices for Safety During Metal Frame Building Projects

When embarking on a metal frame building project, safety should be the top priority for every beginner. First and foremost, it’s critical to wear appropriate personal protective equipment (PPE) such as hard hats, safety goggles, gloves, and steel-toed boots. This gear will shield you from potential injuries caused by falling objects, sharp materials, and accidental slips. In addition, ensure that your workspace is free from clutter and well-lit, which significantly reduces the risk of accidents during construction.

Furthermore, when handling metal frames and related tools, proper training and technique are essential. Before starting, familiarize yourself with the tools you'll be using, such as welders, saws, and lifts. Follow all manufacturer guidelines and safety manuals to prevent mishaps. Always use tools in their intended manner, and if you are unsure how to operate a specific tool, seek guidance from an experienced individual. Implementing these safety practices not only protects the workers but also fosters a more efficient workflow, allowing projects to progress smoothly and effectively.

Safety Measures During Metal Frame Building Projects

Related Posts

-

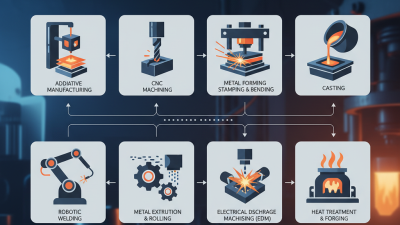

Top 10 Metal Manufacturing Techniques for Efficient Production

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

How to Choose the Right Steel Metal for Your Project

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025