Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Build a Steel Frame Building Efficiently and Cost Effectively?

Building a steel frame building is an appealing choice for many construction projects. This method offers durability and strength, making it ideal for various structures. However, efficient and cost-effective construction requires careful planning and execution.

A steel frame building must be designed thoughtfully to meet specific needs. Cost overruns can happen if the design does not account for local building codes and site conditions. Selecting the right materials is also vital. Quality steel can save money in the long run, reducing maintenance needs.

Detailing the construction process is equally important. Every step, from foundation to framing, should be monitored closely. Common pitfalls include miscalculating labor costs or underestimating time on-site. Learning from these experiences can improve future projects. Building a steel frame building not only demands technical skills but also flexibility and foresight.

Understanding the Benefits of Steel Frame Construction in Modern Building

Steel frame construction offers numerous benefits for modern buildings. It is exceptionally strong and can support large structures. Builders often appreciate the speed of assembly. Steel frames can be pre-fabricated off-site, which reduces construction time. This efficiency can lead to lower labor costs. Additionally, steel is highly durable. It withstands harsh weather conditions much better than wood. This reduces the need for frequent repairs.

Tip: Always consider local climate impacts when planning your project. Steel may rust in areas with high humidity if not treated properly. Regular maintenance is crucial, even though steel is durable.

This building method also promotes sustainability. Steel is recyclable and often made from recycled materials. Using steel can lower the overall environmental impact. However, sourcing steel can lead to logistical issues and costs. It's important to evaluate suppliers carefully.

Tip: Check for local steel suppliers to reduce shipping costs and improve efficiency. Local sourcing can enhance community relationships too. Developing a network of reliable suppliers may take time but can prove invaluable.

Benefits of Steel Frame Construction

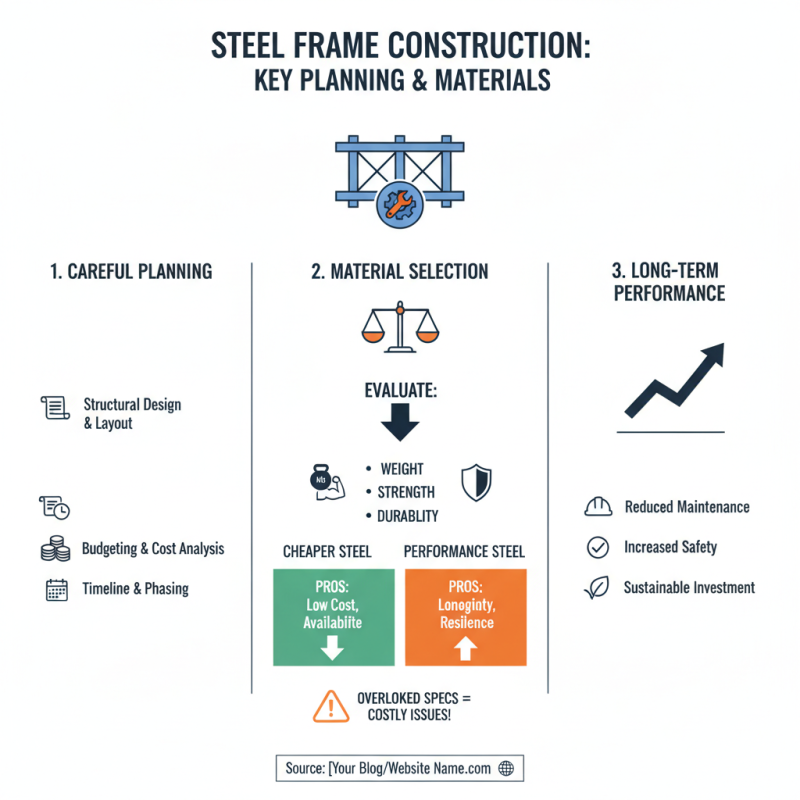

Key Steps in Planning and Designing a Steel Frame Building Efficiently

When planning a steel frame building, clarity is crucial. Start with your objectives. Define the purpose of the building. Is it for residential, commercial, or industrial use? This decision impacts the design and layout significantly. Sketch initial ideas to visualize the space. Move things around. Does the flow make sense? Reflect on this often.

Selecting materials is another vital step. Steel is robust and durable, but it requires precise calculations. Before purchasing, gather different quotes. Compare prices and quality. Mistakes in this phase can lead to unexpected costs. It's easy to overlook small details that impact the overall budget. Always double-check specifications.

Building codes and regulations cannot be ignored. Familiarize yourself with local requirements. Ensure compliance to avoid future setbacks. It’s tempting to rush, but proper planning saves time and resources. Each stage deserves attention and thoughtful consideration. Think of future maintenance needs as well. Plan for longevity, not just immediate gratification.

How to Build a Steel Frame Building Efficiently and Cost Effectively?

| Dimension | Value | Description |

|---|---|---|

| Total Area | 5000 sq ft | Total area of the building |

| Steel Frame Weight | 25000 lbs | Estimated weight of the steel frame |

| Cost per sq ft | $15 | Average cost for construction per square foot |

| Foundation Type | Concrete Slab | Type of foundation used |

| Timeline for Completion | 6 months | Estimated time to complete the project |

| Number of Stories | 2 Stories | Number of floors in the building |

Cost Estimation Techniques for Steel Frame Construction Projects

Cost estimation is a crucial part of steel frame construction projects. Accurate estimates can save time and money. Begin by gathering data on material costs, labor rates, and overhead expenses. These figures should come from reliable sources. Use historical data from past projects as a reference. It helps in identifying potential fluctuations in costs.

Tips: Always include a contingency budget. Projects often face unexpected expenses. A 10% to 15% buffer can provide flexibility.

Consider using software tools for estimation. These programs can streamline the process. They analyze data efficiently and help highlight discrepancies. Manual calculations might lead to mistakes. However, software can also become cumbersome if not updated. Flexibility in the tool is essential.

It’s vital to revisit your estimates regularly. Market prices change. Labor availability can fluctuate, too. Be ready for these shifts. Adjust your budget accordingly. This reflection can enhance future estimates significantly. A proactive approach pays off in the long run.

Optimizing Material Selection and Procurement for Steel Frame Buildings

Building a steel frame structure requires careful planning. Material selection plays a critical role in both efficiency and cost. It's essential to evaluate the weight, strength, and durability of various steel types. Some steel, while cheaper, might not offer long-term performance. Sometimes, overlooked specifications can lead to costly issues later.

Procurement processes are equally important. Bulk purchasing can reduce costs significantly. However, managing inventory levels is tricky. Too much stock can tie up funds, while too little can delay construction. Ideally, a balance is necessary. Regular supplier evaluations can prevent misunderstandings and ensure quality. Communication is key in this phase.

Sometimes, mistakes in planning arise. Have you accounted for local availability of materials? Not all regions have equal access to steel resources. A quick check can avoid future complications. It's important to reflect on your strategy often. This ensures that the project remains on track and within budget. Costs can spiral if material choices are not aligned with actual needs.

Implementing Best Practices for Effective Steel Frame Assembly and Safety

When assembling a steel frame building, safety should always come first. Workers should wear proper gear, including helmets, gloves, and steel-toed boots. Hazards are everywhere at a construction site. Loose materials can cause tripping. Ensuring a clean and organized workspace helps minimize risks. Regular safety meetings can keep everyone informed about potential dangers.

Best practices also focus on effective assembly techniques. Using the right tools makes a huge difference. Wrenches and hoists should be inspected daily. Are they functioning well? If not, replace them immediately. Inadequate tools can slow down the process and lead to accidents. Additionally, training new workers on assembly methods ensures a smoother workflow.

Reflect on the assembly process regularly. Are there areas that create delays? Taking time to identify and address these inefficiencies can improve productivity. Open lines of communication among team members can uncover hidden issues. Learning from mistakes is crucial to evolving. Emphasizing both safety and efficiency paves the way for successful projects.

Related Posts

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

How to Succeed in the Metal Industry Tips for Growth and Efficiency

-

Top 10 Best Metal Processing Techniques for Efficient Manufacturing

-

What is the Impact of Steel Industries on Global Economy and Environment?

-

2025 Top Trends in Steel Stamping: Techniques, Industries, and Innovations