Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Choose the Right Steel Metal for Your Project

Choosing the right steel metal for your project is a critical decision that can significantly impact its durability, performance, and cost-effectiveness. According to the World Steel Association, global steel production reached 1.9 billion metric tons in 2021, indicating the crucial role steel plays in various industries, including construction, automotive, and manufacturing. A fundamental understanding of the types of steel metals available and their properties is vital for engineers and project managers aiming to select the most suitable material that meets specific project requirements.

Expert insights emphasize the importance of informed choices in steel metal selection. Dr. Emily Stone, a prominent metallurgist with over 20 years of experience in the field, states, "The correct selection of steel metal not only enhances the longevity of the project but also optimizes the overall budget." By recognizing the different grades, compositions, and treatment processes of steel metals, professionals are better equipped to make decisions that balance functionality and cost. Understanding these factors, combined with industry trends and technological advancements, can lead to more efficient project outcomes while maintaining high safety standards.

Factors to Consider When Selecting Steel for Your Project

When selecting the right steel for your project, several critical factors must be taken into account. First and foremost, consider the specific application of the steel. Different projects may require varying levels of strength, ductility, and corrosion resistance. For instance, if the steel is to be used in a marine environment, opting for stainless or weather-resistant steel can help ensure longevity and performance. Additionally, the load-bearing requirements will dictate the grade and thickness of steel needed, which is essential for structural integrity.

Another important aspect to consider is the manufacturing process and the resulting steel properties. Steel can be processed in various ways—such as hot-rolling and cold-working—which can impact its characteristics. Understanding the differences in tensile strength, yield strength, and hardness between these processes will assist in determining the best choice for your project's needs. Moreover, environmental factors, including temperature and exposure to chemicals, should also influence your selection, as these can affect the steel’s performance over time. Careful consideration of these elements will lead to a more effective and efficient use of steel in your construction or manufacturing project.

Another important aspect to consider is the manufacturing process and the resulting steel properties. Steel can be processed in various ways—such as hot-rolling and cold-working—which can impact its characteristics. Understanding the differences in tensile strength, yield strength, and hardness between these processes will assist in determining the best choice for your project's needs. Moreover, environmental factors, including temperature and exposure to chemicals, should also influence your selection, as these can affect the steel’s performance over time. Careful consideration of these elements will lead to a more effective and efficient use of steel in your construction or manufacturing project.

Types of Steel Alloys and Their Properties

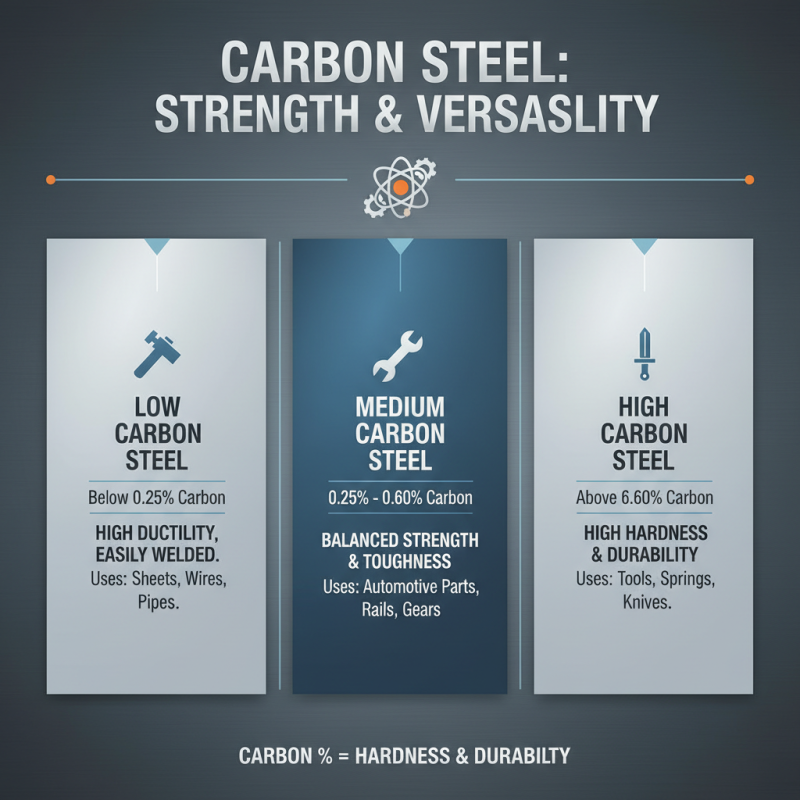

When choosing the right steel alloy for your project, understanding the various types of steel and their intrinsic properties is essential. Steel alloys can be broadly categorized into several categories based on their composition. For instance, carbon steel is one of the most commonly used types, recognized for its strength and versatility. It typically contains varying amounts of carbon, which enhances its hardness and durability. The most notable grades include low, medium, and high carbon steels, each serving different applications depending on the needed strength and ductility.

Another crucial category is alloy steel, which incorporates additional elements such as chromium, nickel, or molybdenum to improve specific characteristics like toughness or corrosion resistance. Stainless steel, a popular subset of alloy steel, contains a minimum of 10.5% chromium, yielding high corrosion resistance, making it ideal for environments prone to moisture and aggressive chemicals. Additionally, tool steel is known for its hardness and ability to retain shape under high temperature, making it suitable for manufacturing tools and dies. Each type of steel alloy comes with its unique properties, and selecting the right one can significantly impact the performance and longevity of your project.

Understanding the Applications of Different Steel Grades

When selecting the appropriate steel for a project, understanding the diverse applications of different steel grades is crucial. Steel is categorized into various grades, each with unique properties that make it suitable for specific uses. For instance, carbon steel is widely used in construction due to its strength and versatility. It is often employed in structural beams, pipes, and reinforcement bars, making it a staple in the building industry.

On the other hand, stainless steel, known for its corrosion resistance, is ideal for applications in environments that are exposed to moisture or chemicals. This grade of steel is commonly found in kitchen utensils, medical equipment, and architectural details. Additionally, alloy steels, which can include elements like chromium, nickel, or molybdenum, offer enhanced strength and durability, making them suitable for manufacturing tools and machinery components. Understanding these characteristics can guide project managers and engineers in choosing the right steel that aligns with their project requirements and environmental conditions.

How to Choose the Right Steel Metal for Your Project - Understanding the Applications of Different Steel Grades

| Steel Grade | Application | Strength (MPa) | Corrosion Resistance |

|---|---|---|---|

| A36 | Structural Steel | 250-400 | Low |

| 304 | Kitchen Equipment | 520-720 | High |

| 4130 | Aerospace & Automotive | 560-650 | Medium |

| 420 | Cutting Tools | 600-900 | Low |

| S235 | General Fabrication | 235-360 | Low |

The Role of Corrosion Resistance in Steel Selection

Corrosion resistance is a crucial factor to consider when selecting steel for any project. Different steel alloys exhibit varying levels of susceptibility to oxidation, rust, and degradation due to environmental factors. Understanding the environment in which the steel will be used—such as exposure to moisture, chemicals, or saline conditions—can guide the selection process. For instance, stainless steel, known for its chromium content, offers higher resistance to corrosion and is often ideal for applications exposed to harsh conditions, such as marine environments or food processing industries.

Another important aspect of corrosion resistance is the long-term implications on durability and maintenance costs. While some corrosion-resistant steels may come with a higher initial price tag, their longevity can lead to significant savings over time by reducing the need for repairs or replacements. Additionally, projects that prioritize aesthetics, like architectural structures, may benefit from using corrosion-resistant materials, ensuring not only functionality but also maintaining visual appeal. Therefore, assessing both the project requirements and the environmental impact can help ensure the right choice of steel is made to enhance longevity and performance.

Cost vs. Performance: Finding the Right Steel for Your Budget

When selecting steel for a project, the balance between cost and performance is crucial. Different types of steel exhibit varying properties, which can significantly impact both the overall budget and the performance of the finished product. For instance, carbon steel is often more affordable and suitable for construction purposes, while stainless steel, although more expensive, offers superior corrosion resistance, making it ideal for environments exposed to moisture or chemicals.

Additionally, considering the long-term implications of your steel choice is essential. While a lower-priced option may seem attractive initially, the overall performance, maintenance costs, and lifespan of the material could lead to higher expenses over time. Projects that require high strength and durability might benefit from investing in alloy steels, which provide excellent mechanical properties but come at an increased cost. By carefully evaluating project requirements and total cost of ownership, you can make an informed decision that balances your budget with the necessary performance characteristics.

Related Posts

-

Top 10 Essential Metals and Materials for Your Next Project

-

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

Top 10 Benefits of Aluminum Metal Everyone Should Know

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide