Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

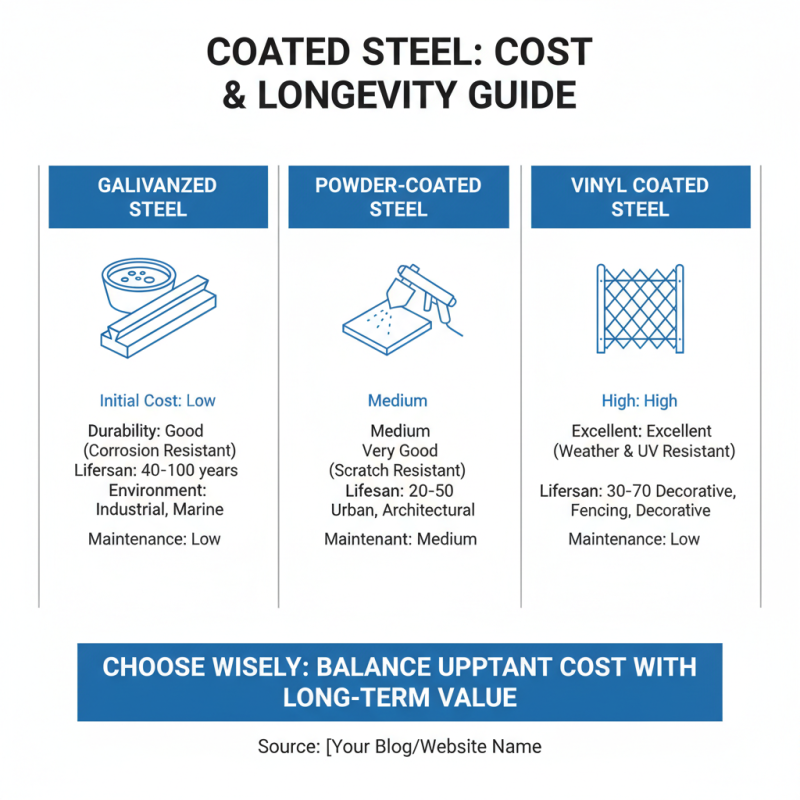

How to Choose the Right Coated Steel for Your Project Needs?

Choosing the right coated steel for your project is crucial. The material's properties can significantly impact the outcome. Coated steel provides durability, corrosion resistance, and aesthetic appeal.

When selecting coated steel, consider the specific needs of your project. Think about environmental factors and load requirements. High humidity environments may require more robust coatings. Some projects may overlook the importance of finish. This can lead to issues in the long run.

It's essential to evaluate the available options carefully. Not all coated steel is created equal, and manufacturers differ. You might find a perfect solution, yet it may not be readily available. Reflection on the quality versus cost is necessary. This analysis can improve the final choice and project success.

Understanding Coated Steel Types and Their Properties

Coated steel comes in various types, each with distinct properties. Understanding these can help you choose the right one for your project. For instance, galvanized steel is coated with zinc. This provides excellent corrosion resistance. It's ideal for outdoor applications. Consider the environment where your project will be. Humidity and exposure to salt can affect durability.

Another option is polymer-coated steel. This type offers an aesthetic appeal. It comes in various colors and finishes. However, it may not resist high heat. Be cautious if your project involves heat exposure. Always check the specifications carefully.

Tips for your selection: Inspect the coating thickness. A thicker layer typically means better protection. Evaluate the application method, too. Some coatings are better suited for specific techniques. Finally, always consult technical data sheets. They can provide insights missed in surface information.

Coated Steel Types and Their Properties

Evaluating Project Requirements for Coated Steel Selection

When selecting coated steel for a project, it is essential to evaluate specific project requirements. Consider the environment where the steel will be used. Will it face harsh weather conditions? High humidity or salt exposure can lead to rapid corrosion. Think about whether the steel will be indoors or outdoors. Indoor environments might tolerate different coatings.

Next, assess the mechanical properties needed. Will the project require high strength and durability? Different coatings offer varying levels of impact resistance. A project demanding heavy loads might not benefit from a thinner coat. Reflect on the life expectancy required for your project. Short-term solutions may not need as robust a coating as long-term investments.

Another key factor is aesthetics. Coated steel can dramatically change the appearance of a structure. Color and texture choices can impact visual appeal. Some clients prioritize appearance over durability. Often, this can lead to unexpected maintenance issues later. Ensure that client expectations align with the project’s design and function before making a decision.

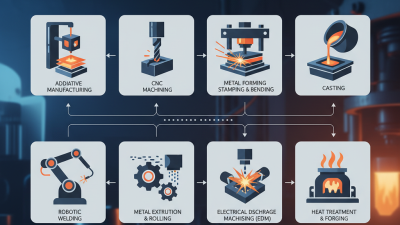

Comparing Coating Processes and Their Impacts on Performance

When selecting coated steel for a project, the coating process impacts performance significantly. Various methods exist, each with distinct strengths and weaknesses. For instance, hot-dip galvanizing offers superior corrosion resistance. However, the cost may be higher than other methods. A recent industry report noted that 78% of professionals prefer this process for long-term durability. Yet, it's not suitable for all applications.

Electrostatic spraying is another method commonly used. It allows for a uniform finish and can be more cost-effective. This method accounts for about 15% of the market share in coated steel production. But, it may lack the longevity seen in galvanizing. In specific environments, deterioration can occur faster than anticipated.

Tips: Always assess the project's environment. Understanding corrosion factors is crucial. Select a process that aligns with expected lifespan and maintenance plans. Make sure to evaluate the initial costs versus long-term benefits. It's important to consider how imperfections in the chosen method can lead to future issues. Not every process will deliver satisfactory results in every scenario. Reflection on these aspects can prevent costly mistakes down the line.

How to Choose the Right Coated Steel for Your Project Needs? - Comparing Coating Processes and Their Impacts on Performance

| Coating Process | Durability | Corrosion Resistance | Application Method | Typical Use |

|---|---|---|---|---|

| Galvanization | High | Excellent | Dip Coating | Construction, Automotive |

| Powder Coating | Moderate to High | Good | Electrostatic Spray | Furniture, Appliances |

| Electroplating | Moderate | Fair | Electrolytic Process | Electrical Components, Fasteners |

| Paint Coating | Low to Moderate | Moderate | Spraying, Brushing | Decorative Items, Automotive |

| Galvalume | High | Excellent | Hot-Dip Coating | Roofing, Wall Panels |

Assessing Cost Factors in Coated Steel Options

When considering coated steel options for your project, it's vital to assess cost factors carefully. Prices can vary widely based on the type of coating used. Popular coatings include galvanized, powder-coated, and vinyl. Each type responds differently to environmental stressors, which impacts overall longevity. A lower initial cost might lead to higher maintenance expenses later.

Evaluate the coating's resistance to rust and corrosion too. Some coatings offer better protection than others, but they may come at a premium. For example, while galvanized steel typically costs less upfront, its lifespan might be shorter in harsher conditions compared to stainless steel options. Think about the long-term implications.

Remember, other hidden costs could arise during installation. Labor costs can fluctuate based on the coating type. Some finishes require special handling. Unexpected delays can also inflate the budget. It’s essential to weigh these aspects when making your decision. Balancing upfront costs with potential long-term savings can be tricky, but it's necessary. Consider the environment your coated steel will face, and reflect on those conditions to make an informed choice.

Identifying Environmental and Durability Considerations in Coated Steel

When selecting coated steel, understanding environmental and durability considerations is essential. The coating type can directly influence a structure's lifespan and performance. According to a report by the International Zinc Association, galvanized steel can last up to 70 years in certain environments. Yet, environmental factors such as humidity, salinity, and temperature fluctuations can significantly reduce this longevity.

Durability also relates to how well the coating withstands wear and tear. For example, powder coatings offer excellent resistance to chipping and scratching. However, they are less effective in extreme heat compared to galvanized options. It's crucial to analyze the specific conditions your project will face. A 2020 study from the Steel Construction Institute found that 95% of project failures were linked to inadequate material selection based on environmental exposure.

It's important to acknowledge that there is often a trade-off with coated steel options. While a more protective coating may offer enhanced performance, it can also lead to higher costs. This complicates decision-making, as budget constraints can force compromises on material choice, potentially affecting long-term durability. Understanding these nuances can help engineers make informed choices for their projects.

Related Posts

-

How to Choose the Right Material for Your Science Project Successfully

-

What is the Impact of Steel Industries on Global Economy and Environment?

-

Metal Coating Tips for Best Durability and Protection?

-

Top 10 Best Metal Processing Techniques for Efficient Manufacturing

-

Top 10 Metal Manufacturing Techniques for Efficient Production

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide