Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

Choosing the right metal coating for your projects can significantly impact the durability, appearance, and overall performance of the finished product. With a plethora of options available, each offering unique benefits and characteristics, it is essential to understand the specific requirements of your project before making a decision. Metal coating serves as a protective layer, safeguarding the underlying material from corrosion, wear, and environmental factors, while also enhancing aesthetic appeal.

In this comprehensive guide, we will explore the various types of metal coatings available, including their respective advantages and applications. Whether you are working on automotive parts, industrial equipment, or decorative items, selecting the appropriate metal coating can help ensure optimal longevity and effectiveness. By considering factors such as material compatibility, expected exposure conditions, and desired finish, you can navigate the selection process with confidence and achieve the best results for your project. Join us as we delve into the essential aspects of metal coating to equip you with the knowledge necessary for informed decision-making.

Understanding the Basics of Metal Coatings and Their Functions

Metal coatings play a crucial role in enhancing the longevity and performance of metal surfaces. These coatings serve various functions, including corrosion resistance, aesthetic appeal, and wear protection. Understanding the different types of metal coatings available is essential for selecting the right one for your project. Common types include galvanizing, powder coating, and electroplating, each offering unique benefits tailored to specific applications.

Galvanizing involves applying a zinc layer to protect steel from rust and oxidation, making it an ideal choice for outdoor structures.

Powder coating, on the other hand, provides a durable and attractive finish by applying a dry powder that is then cured under heat, which enhances both appearance and resistance to scratches and chemicals.

Electroplating allows for a thin layer of metal to be deposited onto another metal, providing improved conductivity and corrosion resistance.

By understanding these coating processes, one can make informed decisions that align with the project's requirements and environmental considerations.

Types of Metal Coatings: Pros and Cons of Each Option

When selecting a metal coating for your projects, it's crucial to understand the different types available, each with its own set of advantages and disadvantages. One popular option is powder coating, which provides a durable finish resistant to scratches, fading, and chipping. This method is environmentally friendly, as it produces minimal waste and VOC emissions. However, it may require a complex application process and can be challenging to repair if damaged.

Another option is galvanization, particularly hot-dip galvanization, which involves coating metal with a layer of zinc to protect it from corrosion. This method is well-suited for outdoor applications, as it creates a robust barrier against various environmental factors. Nevertheless, the appearance may not always be aesthetically pleasing, and the process can be costlier compared to paint or other coatings. Lastly, anodizing, commonly used for aluminum products, enhances resistance to corrosion while providing a range of color options. Although anodized finishes can be appealing, they may not offer as much protection as thicker coatings and can be susceptible to scratches. Each metal coating type presents unique characteristics that should be carefully evaluated based on the specific requirements of your project.

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

| Type of Metal Coating | Pros | Cons | Best Applications |

|---|---|---|---|

| Galvanization | Cost-effective, excellent corrosion resistance | Limited color options, requires proper surface pre-treatment | Construction, automotive components |

| Powder Coating | Durable finish, wide range of colors | More expensive than liquid coatings, requires special equipment | Furniture, appliances, outdoor equipment |

| Electroplating | Improves wear resistance, can enhance appearance | Can be expensive, risk of corrosion under certain conditions | Jewelry, automotive parts, consumer electronics |

| Anodizing | Increases surface hardness, good corrosion resistance | Limited color range, not suitable for all metals | Aerospace components, architectural applications |

| Paint Coating | Easy application, wide variety of colors | Less durable than other coatings, may require frequent maintenance | Automotive, machinery, home use |

Assessing Project Requirements: Environment, Durability, and Aesthetics

When choosing the right metal coating for your projects, assessing the job's specific requirements is crucial. Each project environment poses unique challenges, such as exposure to harsh weather conditions, chemicals, or extreme temperatures.

For instance, outdoor structures might necessitate a coating that offers superior corrosion resistance, while indoor items may prioritize aesthetics and easier maintenance. Identifying these environmental factors early will help narrow down suitable coating options.

Tips: Always consider the location and intended use of the product. Conduct a thorough analysis of potential environmental conditions that could affect the metal's performance and longevity.

Durability is another vital aspect to evaluate when selecting a metal coating. High-performance coatings can significantly enhance the lifespan of the metal surface, protecting it from wear, scratches, and corrosion. For projects subject to heavy use or wear, invest in coatings designed with robust durability in mind, ensuring they can withstand the specific stresses they will encounter.

Tips: Look for test results or certifications regarding the durability of the coatings you are considering. This can give you a better understanding of how they will perform in your particular application.

Aesthetics also play an essential role in your decision-making process. The right coating can enhance the visual appeal of your project, contributing to its overall success.

Consider the color, texture, and finish that will best complement your design vision, as these elements can impact not just attractiveness, but also user experience and satisfaction.

Tips: Don’t hesitate to request samples or swatches before making a final decision, allowing you to visualize how the coating will look in your finished project.

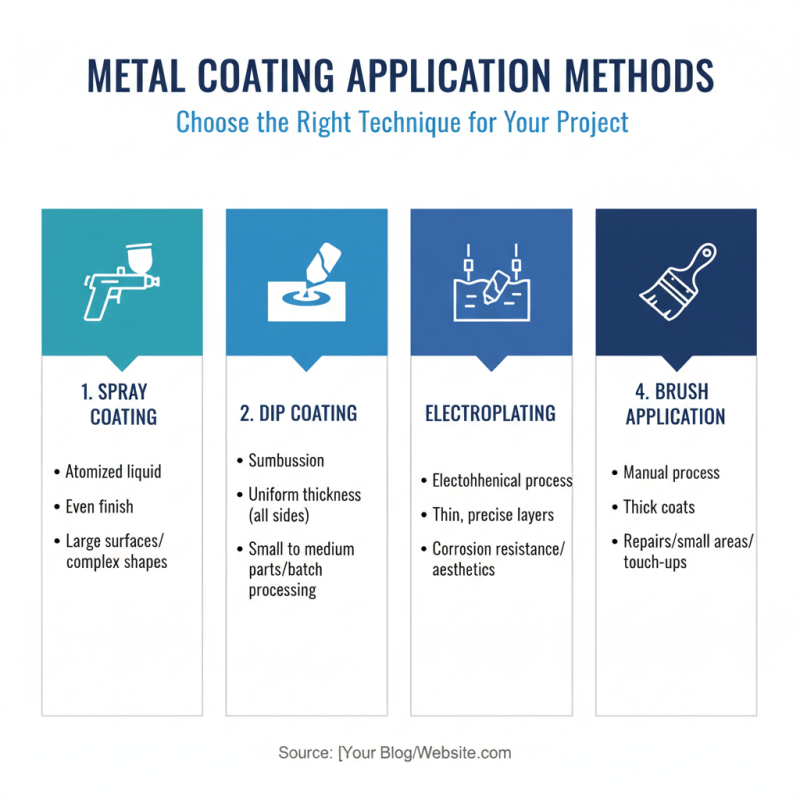

Application Methods: Choosing the Right Technique for Your Project

When selecting the right metal coating for your project, understanding application methods is crucial. The technique you choose can significantly influence the coating's effectiveness and the overall durability of the finish. Common application methods include spray coating, dip coating, electroplating, and brush application. Each of these techniques has its advantages and specific use cases, making it essential to assess the requirements of your project before deciding.

Spray coating, for instance, is prized for its versatility and ability to cover complex shapes evenly. It is suitable for large surfaces but requires adept handling to achieve a uniform finish. On the other hand, dip coating is ideal for items that can be submerged, providing a thick, even layer of coating. This method is particularly beneficial for achieving a seamless finish on small to medium parts. Meanwhile, electroplating is suited for enhancing corrosion resistance and providing aesthetic appeal, as it allows for the deposition of metal on surfaces through an electric current. Each method presents unique benefits and limitations, making it essential to align your choice with the nature of your project and desired outcomes.

Cost Considerations: Budgeting and Value for Different Metal Coatings

When considering metal coatings for your projects, cost should be a significant factor in your decision-making process. Different types of metal coatings, such as powder coating, galvanization, and anodizing, come with varying costs that can affect your overall project budget. It's essential to evaluate both the initial investment and the long-term value of each coating type. While some methods may be cheaper upfront, they might require more frequent maintenance or replacements, leading to higher costs over time.

Additionally, it’s crucial to analyze the specific requirements of your project. Factors such as intended use, environmental exposure, and desired aesthetic can influence both the choice and cost of the coating. For example, coatings designed for heavy-duty applications or extreme conditions may entail higher initial costs but can save money in the long run by extending the life of the metal and reducing the need for repairs or replacements. Balancing these considerations will enable you to choose a coating solution that fits both your budget and your project needs effectively.

Cost Comparison of Different Metal Coatings

Related Posts

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

Top 10 Steel Corporations You Should Know About in 2023

-

How to Choose the Right Material for Your Science Project Successfully

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

Top 10 Essential Metals and Materials for Your Next Project

-

10 Smart Steel Tips for Sustainable Construction and Design Innovations