Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability

Coil coating is a highly efficient and versatile process that plays a crucial role in the manufacturing of various metal products. As industries seek to enhance both aesthetic appeal and the durability of metal surfaces, understanding the nuances of coil coating becomes essential. This ultimate guide aims to provide comprehensive tips and techniques for achieving a superior finish that not only elevates the visual quality of the coated materials but also ensures their longevity in diverse applications.

In reviewing the key elements of coil coating, we will explore essential factors such as surface preparation, coating materials, and application methods. Taking the time to master these aspects can lead to significant improvements in product performance and longevity. Whether you are a seasoned professional or new to the field, this guide is designed to arm you with the knowledge needed to navigate the intricacies of coil coating, ultimately resulting in a stunning and resilient finish that meets the demands of today's dynamic market.

Understanding the Coil Coating Process: Types and Techniques

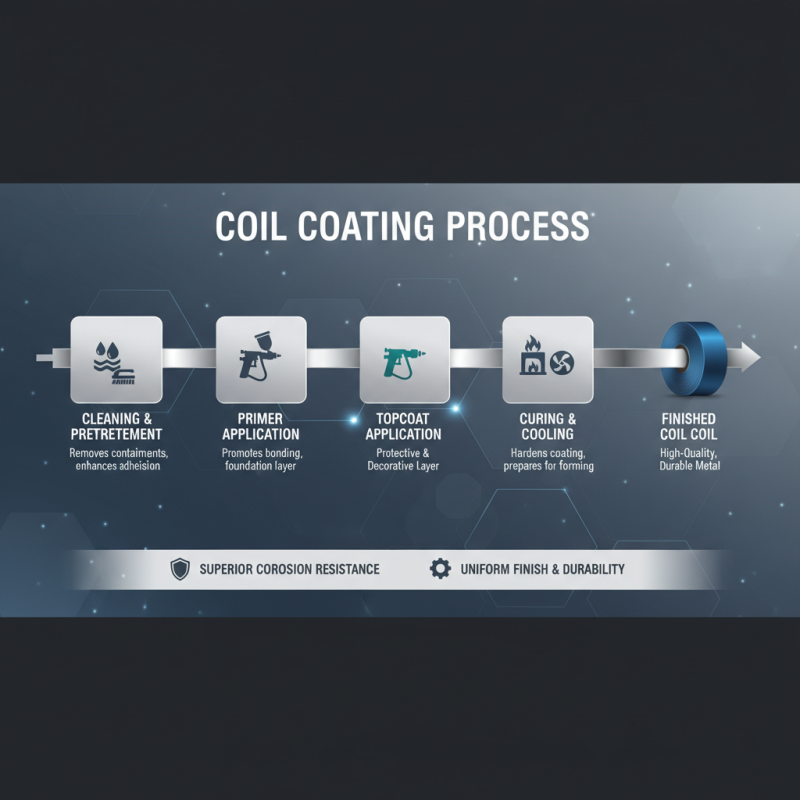

The coil coating process is essential for achieving a high-quality finish and ensuring durability in metal components. This technique involves applying a protective and decorative layer of paint or coating to metal sheets, typically made of steel or aluminum, before they are formed into their final shapes. The process begins with cleaning and pretreating the metal surfaces to remove contaminants and enhance adhesion. Following this, a primer is often applied to promote bonding between the metal and the topcoat, acting as a foundation for the final layer.

There are various types and techniques in coil coating that contribute to the overall quality of the finish. One popular method is the roller coating technique, where liquid coatings are applied through rollers to ensure an even and consistent layer. Additionally, there are different types of coatings available, such as polyester and polyurethane, each offering unique properties for different applications. The curing process, often conducted in a high-temperature oven, solidifies the coatings, providing resistance to scratches, chemicals, and fading. Understanding these elements of the coil coating process can significantly enhance the longevity and aesthetic appeal of coated products.

Key Factors Influencing Coil Coating Performance and Quality

Coil coating is a vital process in the manufacturing of metal products, significantly influencing the finish and durability of the final product. Key factors that impact coil coating performance include substrate preparation, coating thickness, and curing methods. According to a report by the Global Coil Coating Association (GCCA), proper substrate preparation can enhance adhesion by up to 30%, minimizing the risk of delamination and corrosion. Therefore, ensuring that the metal surface is meticulously cleaned and pre-treated is essential for achieving optimal results.

Furthermore, the thickness of the coil coating plays a crucial role in both aesthetics and longevity. Data indicates that coatings with a minimum thickness of 25 microns offer superior resistance to environmental wear compared to thinner alternatives. Additionally, the curing process directly affects the hardness and chemical resistance of the finish. A study published in the Journal of Coatings Technology highlighted that advanced curing techniques, such as infrared heating, can enhance the cross-linking density of the polymer matrix, resulting in a more durable and resilient surface. By focusing on these key factors, manufacturers can significantly improve the performance and quality of coil-coated products.

Importance of Surface Pretreatment in Achieving Durability

Surface pretreatment is a critical step in the coil coating process that significantly influences the longevity and performance of the finished product. Prior to the application of topcoats, surfaces must be meticulously cleaned and prepared to remove any contaminants, such as oils, dust, or rust. This not only enhances adhesion but also prevents defects that could compromise the integrity of the coating. Common pretreatment methods include chemical cleaning, phosphating, and applying conversion coatings, each carefully selected based on the substrate material and the desired end-use characteristics.

In addition to improving adhesion, effective surface pretreatment can provide additional protection against corrosion and environmental damage. When metals are pretreated, they develop a more robust surface profile that helps to anchor the coating firmly. This is especially important in applications where the coated surfaces are exposed to harsh conditions. By investing time and resources into thorough surface preparation, manufacturers can ensure a superior finish that not only meets aesthetic standards but also offers enhanced durability and resistance against wear and tear, ultimately leading to a longer service life for the finished product.

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability - Importance of Surface Pretreatment in Achieving Durability

| Pretreatment Method | Purpose | Benefits | Recommended Thickness (μm) |

|---|---|---|---|

| Chemical Clean | Remove contaminants | Enhances adhesion | 5-10 |

| Mechanical Abrasion | Surface roughening | Increases surface area | 3-5 |

| Phosphate Coating | Corrosion resistance | Promotes long-term durability | 10-15 |

| Chromate Conversion | Protective layer | Minimizes corrosion | 5-7 |

| Chemical Oxidation | Enhances surface properties | Improves coating performance | 7-12 |

Evaluating Coating Thickness: Standards and Measurement Methods

Coating thickness is a critical factor in ensuring the durability and aesthetic quality of coil coatings. According to the American Architectural Manufacturers Association (AAMA), the ideal coating thickness ranges from 0.8 to 2.0 mils for organic coatings, while powder coatings may require a thickness of up to 4.0 mils for optimal performance. Achieving the correct thickness not only enhances the appearance but also significantly improves the lifespan of the coating, helping to resist corrosion, weathering, and wear.

To accurately evaluate coating thickness, several measurement methods are utilized in the industry. The most common techniques include magnetic induction and eddy current testing. Magnetic induction is widely used for ferrous substrates, while eddy current testing is suitable for non-ferrous substrates. A report from the Coating Thickness Measurement Association (CTMA) indicates that employing these methods can lead to a variance of less than ±0.1 mils, thus providing a precise evaluation of the coating's uniformity. Ensuring that the coating thickness adheres to industry standards is crucial for maintaining compliance and fulfilling performance expectations, thereby prolonging the life of the coated material.

Coating Thickness Evaluation for Coil Coating

Troubleshooting Common Coil Coating Issues for Optimal Results

Troubleshooting common coil coating issues is essential for achieving optimal results in your coating processes. Often, problems such as uneven application, color inconsistencies, or adhesion failures can arise, undermining the quality of the final finish. To address uneven application, it's crucial to check the equipment settings, ensuring that the coating system maintains consistent pressure and velocity. Regular maintenance and calibration of the spray nozzles can also help achieve a more uniform coat, preventing streaks or missed areas.

Color inconsistencies may arise due to variation in material inputs or environmental factors. One approach to mitigate this issue is to standardize the mixing process and closely monitor the ambient conditions during application, as temperature and humidity can impact the curing time and appearance of the finish. Furthermore, performing routine checks on the batch quality can help identify any discrepancies before they affect the overall outcome. If you encounter adhesion failures, inspecting the surface preparation process is vital. Ensuring that surfaces are free of contaminants and properly primed can significantly enhance the bond between the substrate and the coating, leading to a durable and aesthetically pleasing finish.

Related Posts

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

-

Top 10 Steel Corporations You Should Know About in 2023

-

Top 10 Essential Metals and Materials for Your Next Project

-

How to Choose the Right Material for Your Science Project Successfully

-

10 Smart Steel Tips for Sustainable Construction and Design Innovations