Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

10 Essential Tips for Choosing the Right Steel Material for Your Project

Choosing the right steel material for your project is a critical decision that can significantly impact both the performance and longevity of your end product. With a myriad of options available, understanding the specific properties and applications of different steel materials is essential for ensuring that your project meets its design and structural requirements. Whether you are involved in construction, manufacturing, or fabrication, the selection of appropriate steel can influence factors such as durability, strength, and sustainability.

In this guide, we will outline ten essential tips to help you navigate the complexities of selecting the ideal steel material. By considering factors such as corrosion resistance, tensile strength, and cost-effectiveness, you will be better equipped to make informed decisions that align with your project's goals. Whether you are an experienced professional or new to the field, these insights will assist you in choosing the right steel material to achieve the best possible outcomes for your project.

Factors Affecting Steel Selection: Strength, Weight, and Durability

Choosing the right steel material for your project is pivotal, and several factors must be considered to ensure optimal performance and durability. Strength is perhaps the most critical characteristic of steel, influencing its ability to withstand loads and stress without deformation. Different applications may require varying strength levels; for instance, structural applications necessitate high-tensile steel, while certain machinery components may rely on softer, more malleable varieties. It's essential to assess the specific loads the material will encounter during its lifetime to select a steel grade that can handle those demands without risk of failure.

Weight is another crucial factor in steel selection. Depending on the project, a lightweight steel may be preferred to reduce the overall mass of structures, aiding in transport and installation. However, lighter steel may compromise strength, so a balance must be struck between reducing weight and maintaining structural integrity. Furthermore, durability plays a significant role in the longevity of the steel used. Factors such as environmental exposure, corrosion resistance, and maintaining performance over time must be weighed to select the appropriate type of steel that will not only meet immediate project needs but also endure through its intended lifespan.

Consequently, evaluating these elements thoroughly will lead to a well-informed decision that aligns with both the technical requirements and lifecycle expectations of the project.

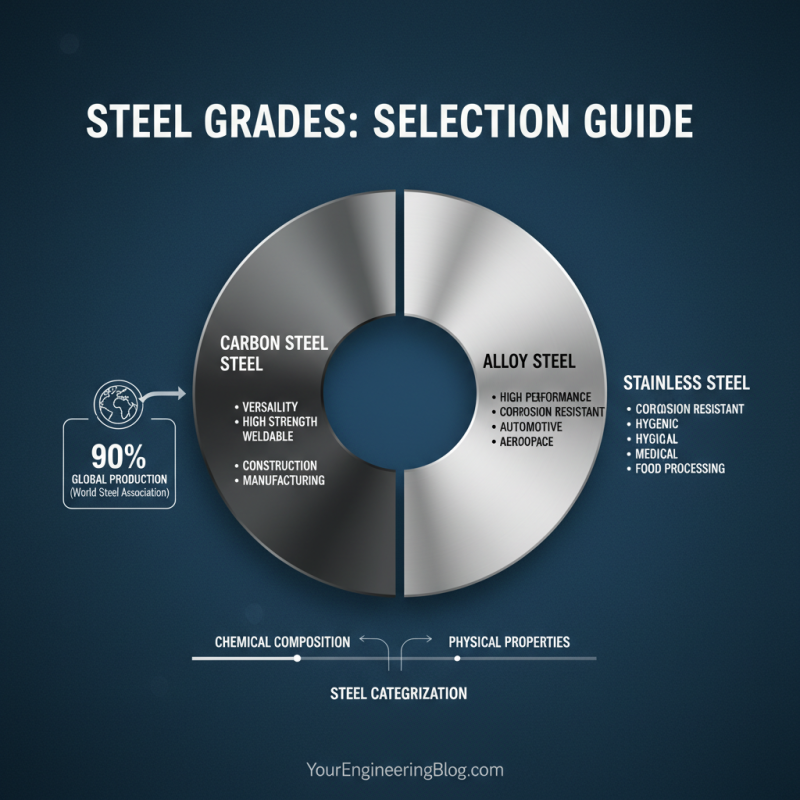

Understanding Different Steel Grades and Their Applications in Projects

When selecting the appropriate steel material for a project, understanding the various grades of steel and their specific applications is crucial. Steel is categorized based on its chemical composition and physical properties. For instance, carbon steel, which is known for its versatility and strength, is often used in construction and manufacturing due to its excellent weldability and formability. According to a report by the World Steel Association, carbon steel accounts for approximately 90% of the global steel production, which underscores its significance across various industries.

Another important category is stainless steel, known for its corrosion resistance and aesthetic appeal. This grade is often utilized in environments that require sanitation and hygiene, such as the food and medical industries. The Global Stainless Steel Report indicates that the demand for stainless steel has seen a steady growth rate of around 5% per year, driven largely by architectural and automotive applications. Understanding each grade's properties ensures the right material is chosen for the specific demands of the project, enhancing durability and performance in the long run.

Moreover, tool steels, which are engineered to withstand high levels of stress and temperature, are primarily used in manufacturing processes that involve cutting and shaping materials. The increased demand for precision tooling in various sectors, including aerospace and automotive, has propelled advancements in tool steel formulations, leading to enhanced performance metrics. A 2021 market analysis projected that the tool steel market will grow at a compound annual growth rate (CAGR) of 4.2% through the next five years, reflecting the ongoing innovation in this material category. Understanding the characteristics and applications of different steel grades is essential for any project manager or engineer aiming to achieve optimal results.

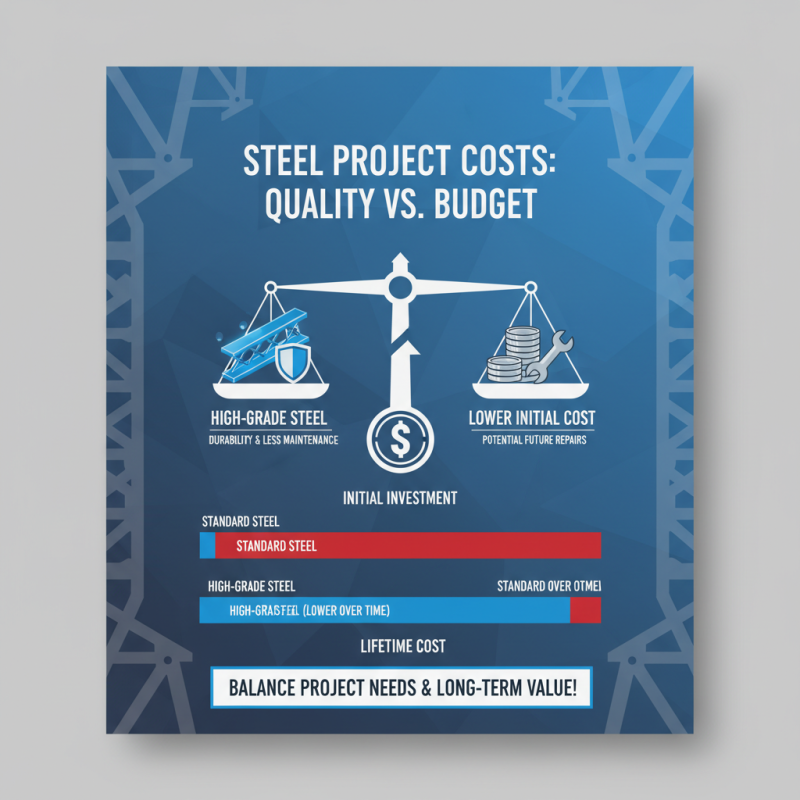

Cost Considerations: Balancing Quality and Budget when Choosing Steel

When embarking on a project that requires steel materials, cost considerations are paramount. Striking a balance between quality and budget is essential to ensure long-lasting results while managing expenses effectively. One must start by assessing the specific requirements of the project. Different types of steel offer varying strengths, corrosion resistance, and durability, influencing their cost. For instance, opting for higher-grade steel may lead to a significant initial investment, but can ultimately save money on maintenance and replacement in the long run.

One essential tip is to compare quotes from multiple suppliers and evaluate the quality of steel they offer. Not all suppliers showcase the same level of craftsmanship or care, which can impact both the longevity of your project and your overall costs. Look for certifications or standards compliance that can provide assurance regarding quality. Another tip is to clearly define the scope of your project; understanding the quantity and types of steel required can prevent over-ordering and help in making informed negotiations with suppliers.

Lastly, consider future maintenance costs when evaluating steel options. While it might be tempting to choose the cheapest material, investing in higher quality steel that requires less maintenance can lead to cost savings over time. By thoughtfully balancing quality with budget constraints, you'll set the stage for a successful and sustainable project.

Environmental Impact: Sustainability in Steel Material Selection

When selecting the right steel material for a project, considering the environmental impact is crucial for promoting sustainability. Steel production is energy-intensive, and the extraction and processing of raw materials contribute to significant carbon emissions. Opting for recycled steel can drastically reduce this environmental footprint, as reprocessing scrap steel requires substantially less energy compared to producing new steel from iron ore. This not only conserves natural resources but also diminishes waste, making recycled steel a favorable choice for environmentally-conscious projects.

Additionally, sourcing steel from manufacturers that prioritize sustainable practices can further enhance the overall sustainability of a project. These manufacturers often adopt eco-friendly production methods, utilize renewable energy sources, and comply with strict environmental regulations. By supporting companies committed to sustainability, project developers can ensure that their choices in steel materials align with broader environmental goals. Furthermore, selecting steel that is designed for durability and longevity minimizes the need for replacements, reducing resource consumption over the product's lifecycle. Integrating these considerations into steel material selection fosters a more sustainable future while also addressing the growing demand for environmentally responsible construction practices.

Environmental Impact of Steel Materials in Project Selection

The following chart illustrates the environmental impact ratings of various steel materials based on key sustainability metrics such as recyclability, energy consumption, and CO2 emissions. Choosing the right steel material can significantly affect the overall sustainability of your project.

Expert Tips on Sourcing High-Quality Steel for Construction Projects

When it comes to sourcing high-quality steel for construction projects, the first step is to establish clear project requirements. Understanding the specific needs of your project, including structural load, environmental conditions, and durability, is crucial. This clarity will guide you in selecting the appropriate steel grade and type. Collaborating with engineers and architects can provide insights into the best material choices, ensuring that the steel meets all necessary standards and specifications.

Next, consider the suppliers and manufacturers you approach. Look for companies with a reputation for reliability and quality in the steel industry. It’s important to request certifications that demonstrate adherence to international quality standards, such as those from regulatory bodies. Additionally, visiting the supplier’s production facility, if possible, can give you a firsthand look at their processes and material handling practices. Establishing a relationship with reputable suppliers can also lead to better pricing and support throughout your project, making the sourcing process smoother and ensuring that you receive the best materials for your needs.

Related Posts

-

How to Choose the Right Steel Metal for Your Project

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

-

Top 10 Benefits of Aluminum Metal Everyone Should Know

-

Top 10 Essential Metals and Materials for Your Next Project

-

10 Smart Steel Tips for Sustainable Construction and Design Innovations