Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

10 Essential Tips to Choose the Right MSC Steel for Your Projects?

Choosing the right MSC steel for your projects is crucial. Experts like John Anderson, a specialist in structural engineering, emphasize this point. He once stated, "The quality of MSC steel can make or break your construction plans."

When selecting MSC steel, consider your project's specific needs. Different applications require varying grades and specifications. It's vital to analyze factors like strength, corrosion resistance, and welding compatibility. Overlooking these can lead to failures or increased costs.

Also, sourcing MSC steel from reputable suppliers is essential. Sometimes, the lowest price might tempt you, but this could compromise quality. Inspecting materials thoroughly before purchase is a must. Maintaining high standards in your choice of MSC steel helps ensure long-lasting structures that meet safety guidelines.

Understanding MSC Steel: Definitions and Types

When selecting the right MSC steel for your projects, understanding its definitions and types is crucial. MSC steel refers to medium-strength cold-formed steel. It offers a blend of strength and ductility. This makes it suitable for various applications, including construction and manufacturing.

There are different types of MSC steel available. These include high-strength, low-alloy, and structural grades. Each type has unique characteristics. For instance, high-strength MSC steel offers enhanced load capacity. On the other hand, low-alloy steels provide improved weldability. Choosing the right type depends on your specific project needs.

Some may overlook the importance of proper selection. This can lead to issues such as insufficient strength or poor durability. Not every project requires the strongest steel. Sometimes, cost-effectiveness is more important. It's essential to weigh the pros and cons. Understanding the types will guide your decision-making process. Mistakes can happen, so it's wise to double-check your specifications.

Evaluating Mechanical Properties for Project Suitability

Choosing the right MSC steel for your projects requires a careful evaluation of its mechanical properties. Strength, ductility, and toughness are crucial factors to consider. A steel's tensile strength indicates how much load it can bear before failing. If the steel isn’t strong enough, projects may face risks. Look for steel that meets or exceeds project requirements. Often, understanding these properties isn’t straightforward.

Ductility is equally important. It measures how much a material can deform before breaking. A ductile steel will absorb energy better under stress. This can prevent sudden failures in critical applications. However, not every project needs high ductility. For some structures, stiffness may be more important. Balancing these properties is a common challenge. Tackling this issue requires careful thought.

Toughness combines strength and ductility, making it essential for many applications. Tough steel can endure impact without fracturing. Evaluating toughness through tests like Charpy impact tests can reveal vulnerabilities. It’s essential to analyze both current and future project conditions. Mistakes in this phase can lead to costly reworks. Your choices today dictate the project’s success later.

Mechanical Properties of Common MSC Steel Grades

This bar chart illustrates the yield strength of various MSC steel grades, highlighting their mechanical properties essential for project suitability.

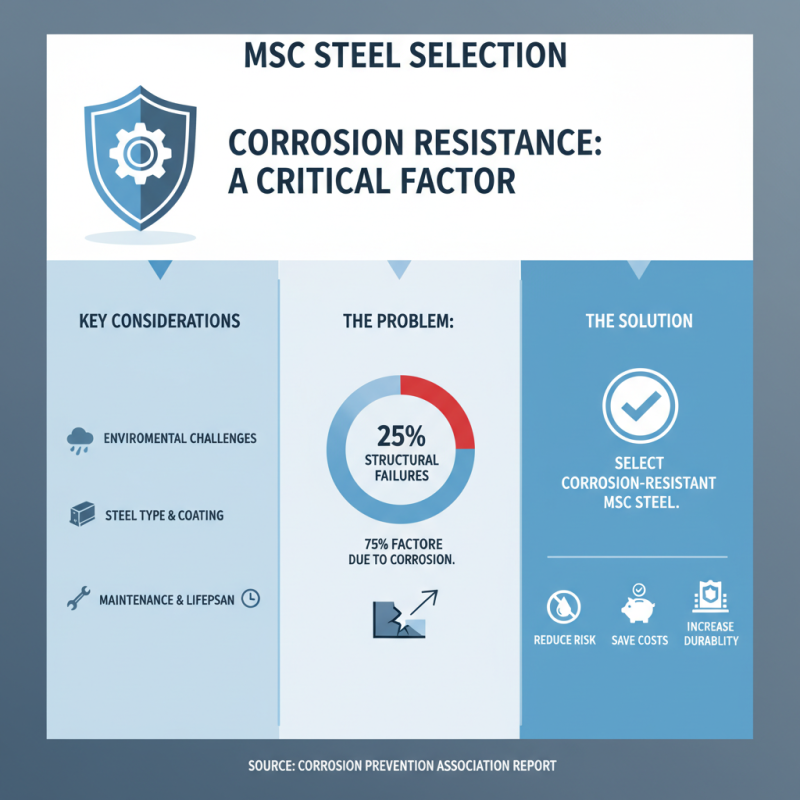

Assessing Corrosion Resistance and Environmental Factors

Choosing the right MSC steel requires a deep understanding of various factors. One of the most critical aspects to consider is corrosion resistance. According to a report by the Corrosion Prevention Association, approximately 25% of structural failures in steel are due to corrosion. This emphasizes the importance of selecting steel that can withstand environmental challenges effectively.

Environmental factors play a significant role as well. For instance, projects located in coastal areas often face saline conditions. A study by the National Association of Corrosion Engineers reveals that corrosion rates can increase by 10% in these environments. Regular assessments of the surrounding environment should be conducted to ensure proper material selection.

Moreover, some alloys perform better in specific conditions. Certain metals might thrive in dry climates yet fail in humid regions. This inconsistency can lead to unexpected maintenance and costs. On top of that, relying only on generic data can overlook unique project needs. Each project demands careful evaluation. Balancing corrosion resistance with environmental factors is essential for long-lasting results in MSC steel choice.

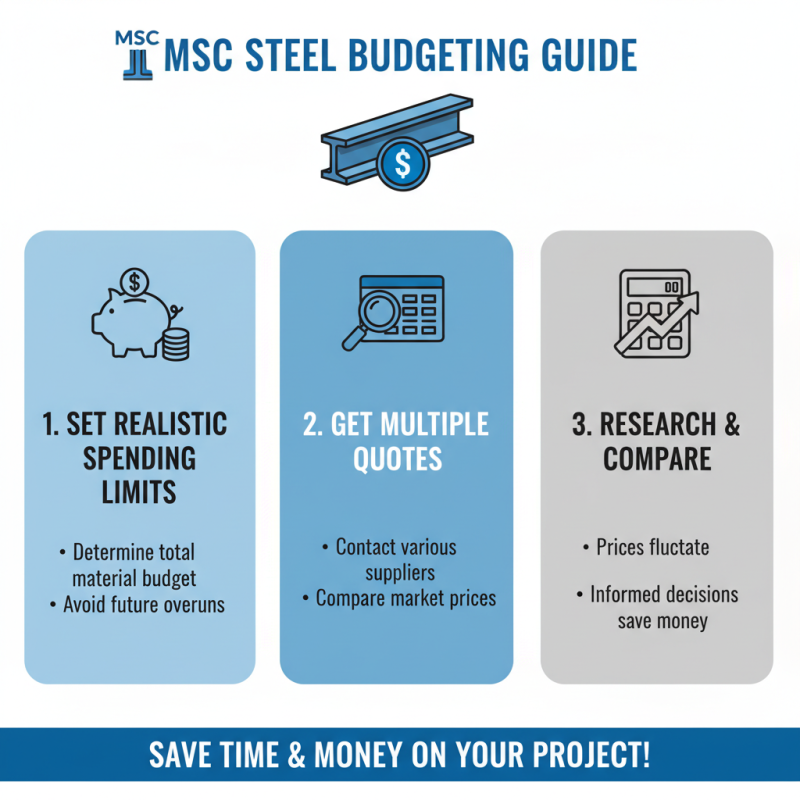

Budgeting and Cost Considerations in MSC Steel Selection

When selecting MSC steel for your project, budgeting plays a crucial role. Determine how much you can realistically spend on materials. This initial step can save you time and prevent costly mistakes later. Quotes from multiple suppliers can help you gauge market prices. Prices may vary significantly, so doing your homework is essential.

Consider not only the upfront costs but also long-term expenses. Higher-quality MSC steel may have a higher price tag but often results in fewer repairs. Cheaper options might save money initially but could lead to unexpected costs down the road. Think about future maintenance and any potential replacements. A well-thought-out budget should anticipate these factors.

Keep in mind that fluctuations in the steel market can affect your budget. Prices can rise and fall based on various economic conditions. Stay flexible and be ready to adjust your plans if necessary. Planning for price changes helps mitigate the risk of overspending. Reflect on what factors are most important and how they fit into your overall budget strategy. Balancing quality and cost requires careful thought and consideration.

Supplier Reputation and Quality Assurance Practices

When selecting MSC steel for your projects, evaluating supplier reputation is crucial. A reputable supplier assures you of quality materials. Research shows that projects using high-quality steel reduce failure rates by over 30%. Therefore, prioritize suppliers with a proven history.

Inspect their quality assurance practices. Look for certifications that validate compliance with industry standards. Regular quality checks can prevent costly errors. Tips to consider include requesting test reports for materials and inquiring about their production processes. Suppliers should be transparent about their sourcing methods.

Reflect on reviews and testimonials. A supplier with consistent positive feedback is likely reliable. Poor reviews, however, may indicate future issues. Always seek diverse opinions from multiple sources. Trusting your supplier can save time and resources, but make sure your decision is well-informed.

10 Essential Tips to Choose the Right MSC Steel for Your Projects

| Criteria | Details |

|---|---|

| Supplier Reputation | Check reviews and testimonials from previous clients. |

| Quality Assurance Practices | Ensure the supplier follows recognized quality standards (ISO, ASTM). |

| Material Certifications | Verify that materials come with necessary certifications. |

| Warranty and Support | Look for suppliers that offer warranty and after-sales support. |

| Pricing Transparency | Ensure clear pricing with no hidden fees. |

| Production Capacity | Assess whether the supplier can meet your project deadlines. |

| Responsive Communication | Evaluate the supplier's responsiveness and customer service. |

| Sustainability Practices | Consider suppliers that adhere to sustainable practices and ethics. |

| Technical Expertise | Choose suppliers with proven technical knowledge in steel production. |

| Delivery Options | Investigate if they provide flexible and reliable delivery options. |

Related Posts

-

Metal Coating Tips for Best Durability and Protection?

-

How to Succeed in the Metal Industry Tips for Growth and Efficiency

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

Top 10 Essential Metals and Materials for Your Next Project

-

2025 Top Trends in Steel Stamping: Techniques, Industries, and Innovations

-

10 Essential Tips for Choosing the Right Steel Material for Your Project