Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Improve Efficiency in Metal Manufacturing Processes in 2025

In the rapidly evolving landscape of metal manufacturing, the drive for enhanced efficiency has never been more critical. As projected by recent industry reports, the global metal manufacturing market is anticipated to reach a staggering $5 trillion by 2025, fueled by advancements in technology and innovative processes. This growth underscores the urgency for manufacturers to adopt strategies that streamline operations and reduce waste, ultimately leading to improved productivity and profitability.

To remain competitive, it is essential for metal manufacturers to integrate cutting-edge technologies such as automation, artificial intelligence, and advanced analytics into their processes. According to a McKinsey report, companies that have implemented these technologies have experienced productivity gains of up to 30%. Additionally, the adoption of sustainable practices not only meets increasing regulatory requirements but also appeals to a growing base of environmentally conscious consumers.

As we navigate through 2025, the focus on efficiency in metal manufacturing will be pivotal. Emphasizing lean manufacturing principles and leveraging data-driven decision-making will allow businesses to optimize their operations, reduce costs, and enhance quality. Ultimately, the future of metal manufacturing lies in a commitment to continuous improvement and innovation, ensuring that companies can meet the demands of a dynamic market while achieving sustainable growth.

Strategies for Implementing Advanced Automation in Metal Manufacturing

In the ever-evolving landscape of metal manufacturing, the implementation of advanced automation technologies is crucial for enhancing operational efficiency by 2025. Industry reports indicate that businesses adopting automation solutions can achieve productivity gains of up to 30% while significantly reducing the error rate in production processes. Advanced robotics, artificial intelligence, and machine learning are at the forefront of this transformation, allowing for real-time monitoring and adjustments that optimize workflow and resource allocation.

One of the key strategies for integrating automation in metal manufacturing is the deployment of smart factories. These environments leverage the Internet of Things (IoT) to connect machines, sensors, and data analytics tools, enabling manufacturers to collect and assess performance metrics instantaneously. According to a recent study by the International Federation of Robotics, the global deployment of industrial robots is projected to reach over 3 million units by 2025, underscoring the trend towards automation. Such systems not only streamline operations but also contribute to predictive maintenance, minimizing downtime and enhancing overall equipment effectiveness (OEE). By investing in these technologies, manufacturers position themselves to meet market demands while ensuring sustainable production practices.

How to Improve Efficiency in Metal Manufacturing Processes in 2025

| Strategy | Description | Expected Efficiency Increase (%) | Implementation Timeframe |

|---|---|---|---|

| Robotic Process Automation | Utilizing robots for repetitive tasks to minimize human error and increase speed. | 20% | 6-12 months |

| Predictive Maintenance | Using IoT sensors to predict machine failures before they occur, thus reducing downtime. | 15% | 3-6 months |

| AI-Driven Quality Control | Implementing AI systems to monitor production quality in real-time, reducing waste. | 25% | 12-18 months |

| Supply Chain Optimization | Improving logistics and inventory management through data analytics and automation. | 18% | 6-12 months |

| Flexible Manufacturing Systems | Adopting modular manufacturing techniques that allow for quick adjustments in production lines. | 22% | 12-24 months |

| Training Programs for Workforce | Implementing continuous education programs to upskill workers on new technologies. | 10% | Ongoing |

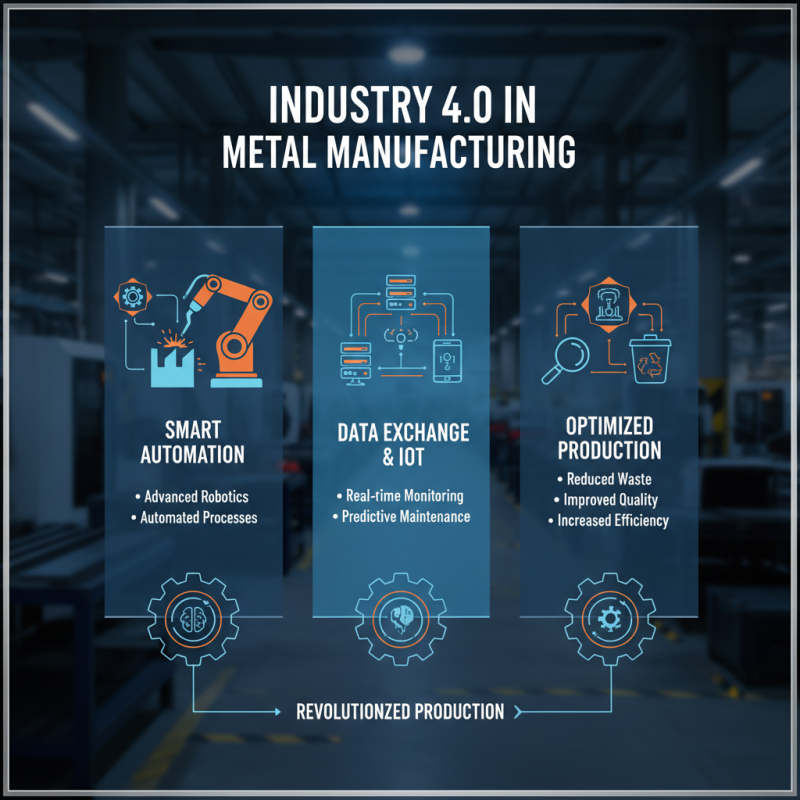

Adopting Industry 4.0 Technologies to Enhance Production Efficiency

The integration of Industry 4.0 technologies into metal manufacturing processes aims to revolutionize production efficiency by leveraging advanced automation, data exchange, and smart manufacturing solutions. By implementing Internet of Things (IoT) devices, manufacturers can gain real-time insights into their operations, allowing for better monitoring of machinery and processes. This data-driven approach enables the early detection of potential issues, reducing downtime and optimizing maintenance schedules. As machines and systems communicate seamlessly, manufacturers can achieve greater precision in production, leading to reduced material waste and improved product quality.

Moreover, the use of artificial intelligence (AI) and machine learning algorithms can enhance decision-making in metal manufacturing. By analyzing vast amounts of operational data, these technologies help predict demand trends and optimize supply chain management. This predictive capability allows manufacturers to adjust their production schedules dynamically, ensuring that resources are utilized effectively and minimizing idle time. Additionally, advanced robotics and automation systems can perform complex tasks at unprecedented speeds, significantly enhancing throughput and accuracy in metal fabrication. Collectively, these Industry 4.0 innovations not only bolster efficiency but also pave the way for a more sustainable and agile manufacturing environment.

Utilizing Data Analytics for Real-Time Monitoring in Metal Processes

In the rapidly evolving landscape of metal manufacturing, leveraging data analytics for real-time monitoring has emerged as a pivotal strategy for enhancing operational efficiency. By integrating advanced data analytics tools, manufacturers can capture and analyze vast amounts of data generated during the production process. This capability allows for immediate insights into machine performance, material usage, and production timelines, facilitating swift adjustments to optimize workflow and mitigate bottlenecks.

Real-time monitoring through data analytics enables proactive decision-making, which is essential for maintaining competitive advantage in the industry. For instance, manufacturers can quickly identify anomalies or inefficiencies in their systems, enabling them to address issues before they escalate into costly downtimes. By utilizing predictive analytics, companies can also forecast maintenance needs, reduce equipment failures, and ensure consistent product quality. This holistic approach not only streamlines operations but also fosters a culture of continuous improvement, where data-driven insights inform strategic initiatives and enhance overall production agility.

Integrating Sustainable Practices to Reduce Waste and Improve Yield

In the quest to enhance efficiency in metal manufacturing processes by 2025, integrating sustainable practices has emerged as a cornerstone strategy. Companies can significantly reduce waste through the implementation of cutting-edge technologies like advanced recycling methods and precision manufacturing. These approaches minimize scrap material generated during production, thus streamlining operations and lowering costs. Additionally, adopting a circular economy model enables manufacturers to reuse materials, transforming what would have been waste into valuable resources.

Moreover, optimizing the yield in metal manufacturing is closely tied to sustainable practices. By investing in energy-efficient machinery and processes, manufacturers can reduce their carbon footprint while simultaneously improving productivity. Techniques such as lean manufacturing not only eliminate inefficiencies but also encourage a culture of continuous improvement among employees. Training staff in sustainable practices fosters innovation, leading to novel solutions that enhance both yield and efficiency. Through these concerted efforts, metal manufacturers can achieve a harmonious balance between profitability and environmental responsibility, paving the way for a more sustainable industry in the years to come.

Training Workforce on Emerging Technologies to Boost Productivity

Training the workforce on emerging technologies is crucial for improving efficiency in metal manufacturing processes, especially as we approach 2025. Automation, artificial intelligence, and advanced robotics are reshaping the landscape of manufacturing. Ensuring that employees are well-versed in these technologies will not only enhance productivity but also foster a culture of innovation within the organization.

Tips: Invest in continuous learning programs that focus on practical applications of new technologies. This hands-on approach allows workers to gain real experience, making them more adept at using advanced tools and machinery. Encourage employees to participate in workshops and online courses that cover the latest trends and advancements in the metal manufacturing industry.

Moreover, implementing mentorship programs can significantly boost knowledge transfer, especially between seasoned workers and those who are new to the field. Such initiatives create an environment where employees feel supported while enhancing their skills.

Tips: Pairing experienced workers with newer employees can accelerate the learning process and help bridge the knowledge gap. Regular training sessions on emerging technologies can keep the workforce updated and engaged, ensuring they are prepared to meet the evolving demands of the industry.

Related Posts

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

Top 10 Benefits of Aluminum Metal Everyone Should Know

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

Top 10 Steel Corporations You Should Know About in 2023

-

How to Choose the Right Material for Your Science Project Successfully

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide