Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

Metal Coating Tips for Best Durability and Protection?

Metal coating plays a vital role in enhancing the durability and protection of various surfaces. It involves applying a layer of metal to create a barrier against environmental hazards. This process is essential for items exposed to moisture, chemicals, or extreme temperatures.

Choosing the right metal coating is crucial. Different metals offer varying degrees of resistance to corrosion and wear. For example, zinc coatings provide excellent rust resistance. However, not every metal will suit every application. It’s important to consider factors like the environment and the material being coated.

While metal coating can prolong the lifespan of products, it is not without challenges. Improper application methods can lead to weak spots, reducing effectiveness. Regular inspections and touch-ups may be necessary, causing added maintenance efforts. Understanding these nuances helps to achieve optimal results in metal coating applications.

Understanding Metal Coating: Types and Their Benefits for Durability

When it comes to enhancing metal durability, understanding various coating types is essential.

Powder coating is one popular method. It provides a tough finish that resists scratches and chemicals. Its application is relatively straightforward. However, improper techniques can lead to uneven surfaces, resulting in weak spots.

Another method is galvanization, where zinc coats steel or iron. This process offers excellent corrosion resistance, increasing the metal’s lifespan. It’s effective, yet the coating can wear off over time, especially in harsh environments. Regular inspections and touch-ups are vital to maintain effectiveness.

Consider anodizing for aluminum, which creates a protective oxide layer. This method improves both appearance and resistance to wear. But anodizing requires specific environmental conditions. If not done right, it can lead to poor adhesion and inconsistent protection. Each method has its pros and cons, and selecting the right one depends on specific needs.

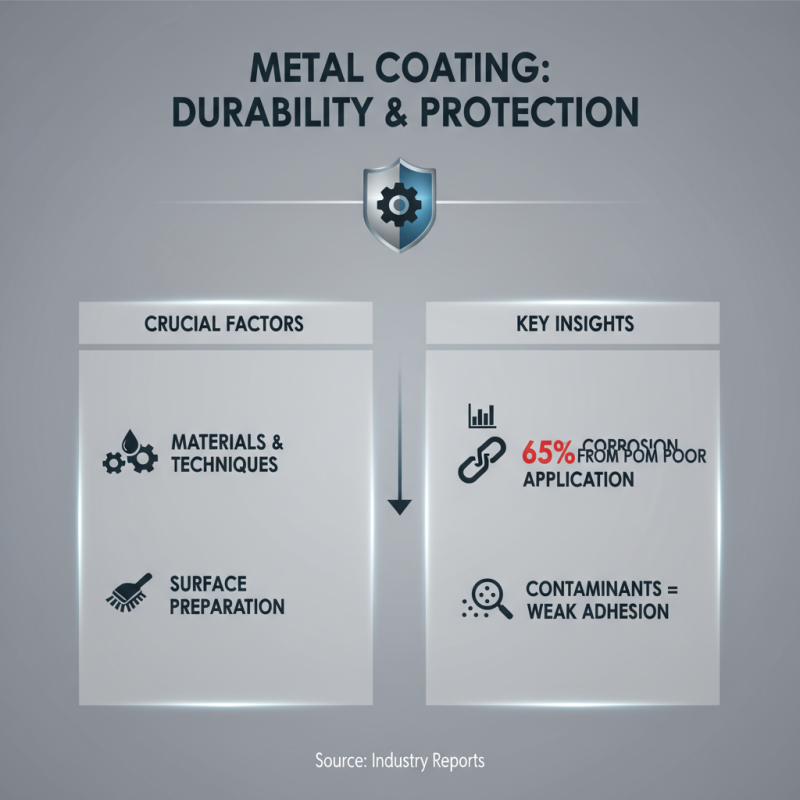

The Science Behind Metal Coating: Materials and Application Techniques

Metal coating is crucial for enhancing durability and protection. The right materials and application techniques greatly influence the longevity of coated items. According to industry reports, over 65% of corrosion-related failures stem from improper coating applications. Accurate surface preparation is vital. Any contaminants can lead to weak adhesion, compromising the entire coating process.

For optimal results, consider these tips. Ensure surfaces are clean and dry before applying coatings. Using a sandblasting technique can remove old coatings and contaminants effectively. Select coatings based on your environmental requirements. For example, epoxy coatings excel in harsh conditions but may lack flexibility.

Moreover, application methods matter. Spray techniques distribute coatings evenly, while dipping can provide thicker layers. Nonetheless, common mistakes occur, such as incorrect curing temperatures. This can significantly affect the performance of the coating. Regular inspections can help identify issues early. Being proactive can save money and resources in the long run.

Key Factors Influencing Metal Coating Longevity and Performance

When it comes to metal coating, several key factors can influence its longevity and performance. Environmental conditions play a vital role. Humidity, temperature fluctuations, and exposure to chemicals can wear down coatings faster than expected. Regular maintenance checks can help identify issues early. Failing to do so may lead to premature corrosion.

Choosing the right coating material is also crucial. Some coatings offer better protection against abrasion and moisture. It's essential to assess the specific environment where the metal will be used. Thick coatings might look appealing, but they can lead to adhesion problems. A thin layer can often provide optimal protection without compromising the bond.

Tips: Always prepare the metal surface thoroughly before applying a coating. This ensures better adhesion and a longer-lasting finish. Additionally, consider using coatings designed for specific applications. These are formulated to provide maximum protection against the conditions they will face. Ignoring these details can result in costly repairs later on. Pay attention to the coating application method, as this affects the final result.

Metal Coating Durability Analysis

Industry Standards and Best Practices for Metal Coating Applications

When considering metal coating applications, following industry standards is crucial for ensuring durability. Proper surface preparation is often overlooked. Many assume that a simple clean will suffice. However, contaminants must be thoroughly removed. Dust, grease, and oxidation can compromise adhesion. Utilize a combination of mechanical and chemical cleaning methods for best results.

Coating thickness is another key factor. Industry standards often recommend specific thickness ranges for different applications. Too thick of a coating can lead to cracking, while a too-thin layer may not offer adequate protection. Regular inspections should be conducted to verify that the coating is meeting standard specifications. It's essential to be aware of variations in application methods too. Techniques like spray coating and dip coating have their own unique challenges and benefits.

Temperature and humidity during application play a significant role. Coating materials behave differently under varying conditions. A sunny day might seem ideal, but high humidity can affect curing. Many applicators tend to forget environmental factors. Ensuring the right conditions can be the difference between a failing and a successful coating job. Reflecting on your processes can help identify areas for improvement.

Evaluating Cost-Effectiveness: Metal Coating vs. Alternative Protection Methods

When evaluating cost-effectiveness, metal coating is often compared to alternative protection methods. Metal coatings offer excellent durability against rust and corrosion. They can significantly extend the lifespan of metal products. However, this durability comes with a price.

Alternative methods, such as paints or sealants, may be cheaper upfront. Yet, they often require more frequent maintenance. Paint can chip or fade, while sealants may peel away. In the long run, these alternatives might not be as cost-effective. Investing in metal coating may save money over time, even if initial costs are higher.

It's vital to consider intended use when choosing a method. If a product experiences heavy wear or environmental exposure, metal coating may be best. On the contrary, for occasional or indoor items, less durable options may suffice. The decision isn’t simply about cost; it also involves assessing risks and potential failures.

Metal Coating Tips for Best Durability and Protection? - Evaluating Cost-Effectiveness: Metal Coating vs. Alternative Protection Methods

| Protection Method | Durability (Years) | Cost per Square Foot ($) | Maintenance Frequency (Years) | Environmental Resistance |

|---|---|---|---|---|

| Galvanization | 20 | 2.50 | 10 | High |

| Powder Coating | 15 | 3.00 | 5 | Moderate |

| Electroplating | 10 | 4.50 | 3 | Low |

| Anodizing | 20 | 5.00 | 7 | High |

| Paint Coating | 5 | 1.50 | 2 | Moderate |

Related Posts

-

Top 10 Benefits of Aluminum Metal Everyone Should Know

-

How to Succeed in the Metal Industry Tips for Growth and Efficiency

-

How to Choose the Right Material for Your Science Project Successfully

-

10 Essential Tips for Choosing the Right Steel Material for Your Project

-

How to Choose the Right Steel Metal for Your Project

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025