Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

Top 10 Smart Steel Innovations Transforming the Industry Today?

Smart steel is revolutionizing the industrial landscape. Innovative technologies are enabling this transformation. The advancements in smart steel not only enhance performance but also address environmental concerns.

These innovations include sensors integrated into steel structures. They monitor health and stress levels in real-time. This can prevent structural failures and reduce maintenance costs. As industries embrace smart steel, new possibilities emerge. Imagine buildings that can communicate their own weaknesses. This leads to safer and more sustainable practices.

However, not all developments are perfect. Some technologies may require extensive research and investment. The implementation process can also be challenging. There are often unexpected hurdles to overcome. Reflecting on these challenges is crucial for future progress. Smart steel holds promise, but its journey is still ongoing.

Revolutionizing Steel: An Overview of Smart Innovations

The steel industry is undergoing a radical transformation. Smart innovations are changing how steel is produced and used. In 2022, global steel production reached 1.9 billion metric tons. Innovations can significantly reduce this number by promoting efficiency.

One index shows that adopting smart technologies can cut energy consumption by up to 30%. Sensors embedded in the production line monitor real-time data. This helps in reducing waste and energy use. Predictive maintenance is another key area. Equipment failures can lead to downtime, costing companies millions. Smart solutions can predict failures before they happen. Yet, the challenge remains; not all companies can afford these technologies.

However, the integration of smart systems is uneven. Some regions advance quickly, while others lag. There's skepticism about the return on investment, and many businesses hesitate. Reports indicate that approximately 40% of manufacturers are still not using any smart technologies. They need further exploration of these innovations. The journey to a fully smart steel industry is ongoing and complex.

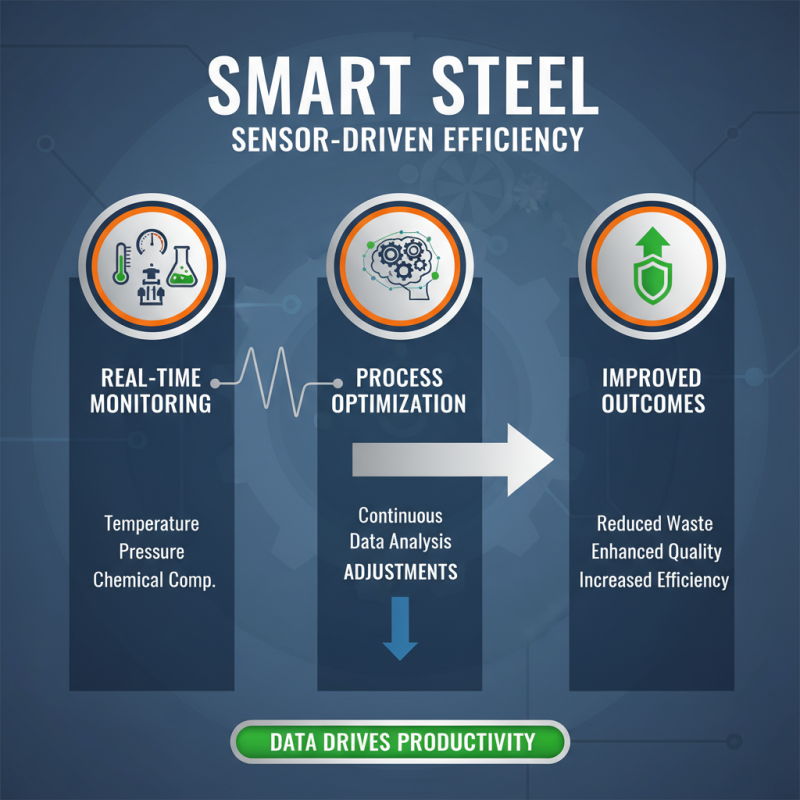

Advanced Sensors in Steel Production and Monitoring Systems

In today's steel industry, advanced sensors play a crucial role in enhancing production efficiency. These sensors monitor various parameters like temperature, pressure, and chemical composition in real-time. By providing continuous data, they help optimize the steel-making process, reducing waste and improving quality.

Implementing these technologies isn’t without challenges. Many facilities struggle with integrating sensors into existing systems. Data overload can occur, making it hard to focus on key metrics. Regular training can help mitigate these issues. Team members need to understand the insights sensors provide for informed decisions.

Tips: Regularly review sensor data to identify trends. Engage in cross-departmental meetings to enhance understanding and promote knowledge sharing. Don't overlook the importance of maintaining sensor accuracy. Small errors can lead to significant production issues.

AI and Machine Learning Applications in Steel Manufacturing

AI and machine learning are revolutionizing the steel manufacturing industry. According to a recent report, using AI can enhance production efficiency by up to 30%. This technology analyzes vast amounts of data in real time. It identifies patterns that human operators might miss. The implications are significant. Factories can reduce waste and improve steel quality.

Predictive maintenance is one area where AI shines. Sensors gather data on equipment performance. Machine learning algorithms predict failures before they happen. This approach can cut maintenance costs significantly. Studies show that companies can save around 10% on their operational expenses by implementing these systems.

However, challenges remain. Implementation costs can be high, and workforce training is essential. Not all facilities are ready for these advanced technologies. Some operators may struggle to adapt to new workflows. This transition can slow down productivity temporarily. It's crucial for the industry to reflect on these hurdles while pursuing innovation. Balancing technology integration with realistic human factors is key.

Sustainability in Steel: Green Innovations and Practices

Sustainability is a critical aspect of modern steel production. Innovations are transforming how steel is made and used. Many companies are exploring ways to reduce carbon emissions. For instance, using renewable energy sources can significantly lower the carbon footprint of steel production. The shift towards electric arc furnaces is gaining momentum. These furnaces can recycle scrap steel more efficiently, minimizing waste.

While there are strides being made, challenges still exist. Not all facilities have access to the latest technology. Some regions rely heavily on traditional methods. This lag prevents them from fully adopting green practices. Moreover, the investment for greener technologies can be high, causing hesitation. It’s crucial to address these gaps to move towards a truly sustainable industry.

Another innovation worth mentioning is the development of biofuels. They can replace fossil fuels in the steel-making process. This could lead to a significant reduction in pollutants. Yet, the scalability of biofuels remains uncertain. Continuous research is needed to evaluate their effectiveness and viability. There is much work ahead as the industry tries to balance innovation with real-world applications.

Smart Steel Alloys: Enhancing Strength and Durability Through Technology

Smart steel alloys are at the forefront of modern advancements in the materials industry. Enhanced strength and durability are crucial for various applications, from construction to automotive. Recent reports show that smart steel can reduce weight by up to 30% while maintaining performance. This innovation leads to more efficient structures and vehicles.

Emeralds are valuable, but smart steel offers unique benefits. With the integration of advanced technologies, alloys now self-heal minor fractures. This means less maintenance and longer lifespans. However, not all smart steels are created equal. Some still face production challenges, leading to inconsistencies in performance.

In construction, using these alloys shows promising results. A study found that buildings made with smart steel can endure extreme weather better than traditional materials. But it's essential to evaluate the environmental impact. High energy consumption during production raises concerns. Balancing innovation with sustainability remains a challenge for the industry.

Top 10 Smart Steel Innovations Transforming the Industry Today

This chart illustrates the advancements in smart steel alloys focusing on key properties such as strength and durability across different innovations within the industry.

Related Posts

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025

-

How to Succeed in the Metal Industry Tips for Growth and Efficiency

-

How to Build a Metal Frame Building: A Step-by-Step Guide for Beginners

-

Top 5 Benefits of Using Coil Coating for Your Architectural Projects

-

10 Essential Tips to Choose the Right MSC Steel for Your Projects?

-

Top 10 Steel Corporations You Should Know About in 2023