Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

How to Succeed in the Metal Industry Tips for Growth and Efficiency

The metal industry is a cornerstone of modern manufacturing, playing a vital role in various sectors such as construction, automotive, and technology. As this industry evolves, companies face an array of challenges that demand innovative approaches to maintain competitiveness and drive growth. Understanding key strategies for success in the metal industry is essential for businesses looking to enhance their efficiency and productivity.

In this ever-changing landscape, companies must adopt practices that not only refine their operational processes but also foster sustainable development. By focusing on areas such as technological advancements, workforce education, and supply chain optimization, organizations can position themselves for long-term success. The following discussion will explore pertinent strategies and insights, equipping metal industry stakeholders with the tools necessary to thrive in an increasingly competitive market.

Understanding the Metal Industry Landscape: Trends and Challenges

The metal industry is experiencing significant transformations influenced by various trends and challenges that shape its landscape. According to a report by Market Research Future, the global metal market is projected to reach a value of approximately $2 trillion by 2026, growing at a CAGR of around 5% from 2021 to 2026. This growth is driven by increasing demand from sectors such as automotive, construction, and electronics. However, the industry must navigate obstacles, including fluctuating commodity prices and environmental regulations that urge companies to adopt sustainable practices.

One of the key trends is the rising importance of automation and digital technologies in the metal sector. A study by McKinsey & Company indicates that companies integrating Industry 4.0 technologies could see productivity improvements of 20% or more. These innovations not only enhance operational efficiency but also allow for better data management and decision-making processes, which are critical in addressing the challenges posed by supply chain disruptions. To remain competitive, industry players must invest in modernizing processes and upskilling their workforce, ensuring they can meet the evolving demands of the market while maintaining profitability and environmental compliance.

Essential Skills for Success in the Metal Industry Workforce

To thrive in the metal industry, honing essential skills is vital for navigating its complexities. Firstly, technical knowledge remains a cornerstone for success. Understanding metallurgy, welding techniques, and safety standards can set candidates apart in an industry that demands precision. Continuous learning through workshops and certifications can deepen this knowledge, making professionals more adaptable and innovative.

Communication is another key skill, particularly in a field often defined by collaboration. The ability to convey technical information clearly to team members and stakeholders enhances project efficiency and reduces errors. Building strong relationships within the workforce can lead to enhanced collaboration and a better understanding of team dynamics.

Here are some tips for growth and efficiency in the metal industry:

1. **Invest in Training**: Regularly participate in skill development programs to stay updated with the latest technologies and techniques.

2. **Embrace Technology**: Utilize advanced software and machinery to streamline operations, reduce waste, and improve productivity.

3. **Cultivate Problem-Solving Skills**: Develop a proactive approach to challenges by encouraging brainstorming sessions, which can lead to creative solutions and a more resilient workflow.

Focusing on these skills and strategies will enable professionals within the metal industry to excel and drive their organizations toward success.

How to Succeed in the Metal Industry: Tips for Growth and Efficiency

| Skill / Area | Description | Importance Level | Growth Potential |

|---|---|---|---|

| Welding Techniques | Proficiency in different welding methods. | High | High |

| Metal Fabrication | Understanding of processes like cutting, bending, and assembling metal. | Medium | Medium |

| Quality Control | Ability to assess and maintain quality standards in products. | High | High |

| Safety Standards | Familiarity with safety regulations and best practices. | Very High | Medium |

| Project Management | Skills in planning and executing projects effectively. | Medium | High |

| Computer-Aided Design (CAD) | Proficiency in using CAD software for designing metal parts. | High | Very High |

| Technical Communication | Ability to communicate technical information clearly. | Medium | Medium |

Strategies for Optimizing Production Efficiency in Metal Manufacturing

Optimizing production efficiency in metal manufacturing is crucial for driving growth and maintaining competitiveness in a fast-paced industry. One effective strategy is to adopt automation technologies. Implementing automated systems can streamline operations, reduce human error, and enhance overall output. Advanced machinery can execute repetitive tasks with precision, freeing skilled workers to focus on more complex responsibilities that require human intuition and expertise.

Additionally, regular maintenance of equipment is essential for minimizing downtime and ensuring consistent performance. Establishing a routine maintenance schedule helps identify potential issues before they become significant problems, allowing for planned downtimes rather than unexpected breakdowns. Workers should also be trained to recognize early signs of wear and tear, empowering them to take proactive measures.

Lastly, fostering a culture of continuous improvement can lead to innovative solutions that boost efficiency. Encourage employees to share their insights and suggestions on process improvements, as they often have firsthand experience with day-to-day operations. Establishing cross-functional teams to explore these ideas can lead to unexpected efficiencies that benefit the entire production process. By combining these strategies, metal manufacturers can not only enhance their operational efficiency but also position themselves for long-term success in the industry.

Innovative Technologies Driving Growth in Metal Industry Operations

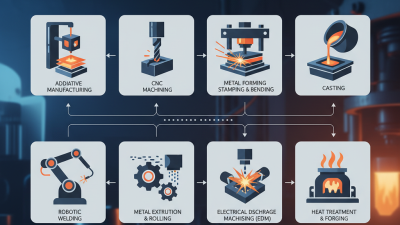

The metal industry is undergoing a significant transformation driven by innovative technologies that enhance growth and improve operational efficiency. One of the key advancements is the integration of automation in production processes. Automated systems increase precision and speed, reducing material waste and labor costs while improving product quality. Robotics in machining, welding, and assembly lines enable manufacturers to scale operations seamlessly and respond to market demands swiftly.

Additionally, data analytics and artificial intelligence (AI) are playing a crucial role in optimizing operations. By harnessing real-time data from machines and supply chains, companies can identify inefficiencies and predict maintenance needs, minimizing downtime. Predictive analytics can also forecast market trends, allowing businesses to align their production strategies with consumer demand effectively. Implementing these technologies not only streamlines operations but also enhances sustainability efforts by minimizing energy consumption and reducing the environmental footprint of metal production.

Moreover, advancements in materials science, such as the development of lighter and stronger alloys, open new opportunities for innovation in various industries, including aerospace and automotive sectors. By embracing these technological advancements, companies in the metal industry can position themselves for growth, adapt to changing market conditions, and ultimately drive long-term success.

Innovative Technologies Driving Growth in Metal Industry Operations

Building Sustainable Practices for Long-Term Success in Metal Production

In the metal industry, building sustainable practices is crucial for ensuring long-term success and minimizing environmental impact. One of the fundamental aspects of sustainability is resource efficiency. Companies can achieve this by implementing advanced recycling processes, which not only reduces waste but also conserves energy and raw materials. By investing in technology that enhances the recovery of metals from scrap and by-products, businesses can streamline their production methods while simultaneously contributing to a circular economy.

Furthermore, integrating renewable energy sources into metal production processes can significantly reduce carbon footprints. Solar or wind energy can be harnessed to power operations, thus lessening dependence on fossil fuels. Additionally, fostering a culture of sustainability among employees through training and awareness programs can lead to innovative ideas that further promote efficient practices. Encouraging teamwork in identifying areas for improvement can enhance operational performance while upholding a commitment to environmental stewardship. These sustainable practices will not only benefit the planet but also position companies favorably in a competitive market.

Related Posts

-

Top 10 Steel Corporations You Should Know About in 2023

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025

-

Top 10 Best Metal Processing Techniques for Efficient Manufacturing

-

Top 10 Metal Manufacturing Techniques for Efficient Production

-

How to Choose the Right Steel Metal for Your Project