Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

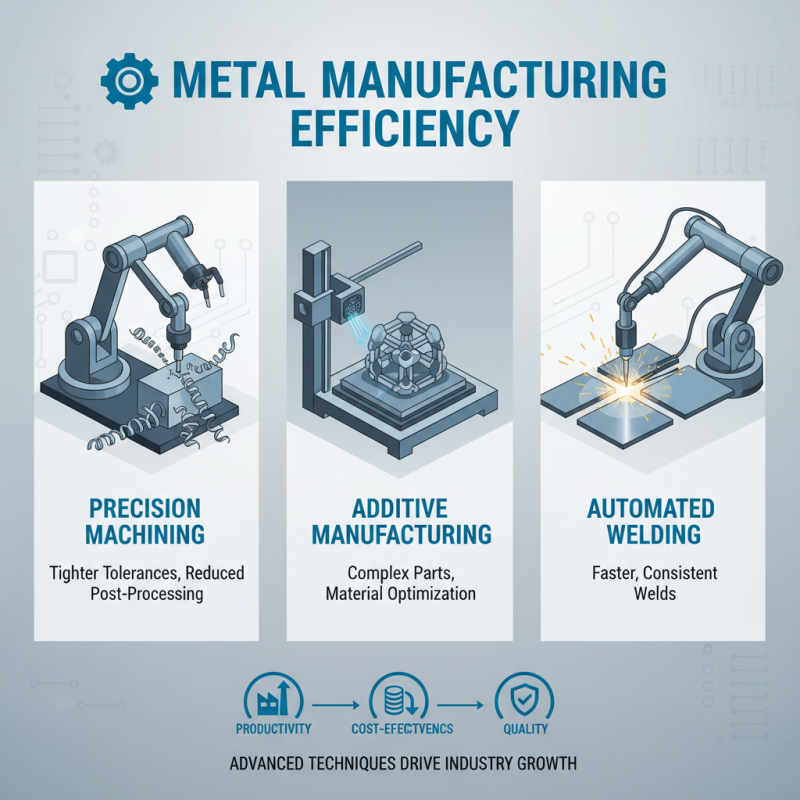

Top 10 Metal Manufacturing Techniques for Efficient Production

The metal manufacturing industry plays a pivotal role in shaping the modern world, providing essential materials for a wide array of applications, from construction to automotive engineering. As manufacturing processes evolve, companies are constantly seeking innovative techniques that enhance efficiency, reduce waste, and improve overall quality. In this context, understanding the most effective metal manufacturing techniques becomes paramount for businesses aiming to remain competitive in a rapidly changing market.

This article delves into the top 10 metal manufacturing techniques that are not only efficient but also contribute to sustainable practices. By exploring advancements in methods such as additive manufacturing, machining, welding, and metal forming, we highlight how these technologies are revolutionizing production processes. Furthermore, an emphasis on efficiency in metal manufacturing can lead to significant cost savings and improved product performance, making it imperative for manufacturers to adopt the best practices outlined in our discussion. Join us as we explore these techniques and their transformative impact on the metal manufacturing landscape.

Top 10 Metal Manufacturing Techniques for Efficient Production

Efficient production in metal manufacturing is vital for meeting the increasing demand across various industries. The utilization of advanced techniques significantly impacts not only the quality of the final products but also the overall productivity and cost-effectiveness of the manufacturing process. Techniques such as precision machining, additive manufacturing, and automated welding have emerged as key methods that enhance efficiency. Precision machining, for instance, allows for tighter tolerances and better surface finishes, reducing the need for extensive post-processing.

Moreover, techniques such as laser cutting and CNC punching provide high levels of automation, enabling rapid production cycles and minimizing material waste. By integrating these advanced processes with robust software solutions, manufacturers can optimize their workflow and improve inventory management. Additionally, the adoption of collaborative robotics in assembly lines offers flexibility and scalability, allowing businesses to adapt quickly to changing market demands. Overall, the strategic implementation of these top metal manufacturing techniques is essential for achieving efficient production and maintaining a competitive edge in the industry.

Understanding Metal Fabrication: Key Processes and Their Applications

Metal fabrication encompasses a variety of processes that are essential for transforming raw metal into functional components. Key techniques include welding, bending, and machining, each serving distinct roles in the production line. Welding joins metal pieces through different methods like MIG and TIG, providing strength and structural integrity. Bending involves the use of high-pressure equipment to shape metal sheets into desired angles, often applicable in industries like automotive manufacturing. Machining, on the other hand, removes material through processes such as milling and turning, allowing for precise shaping and finishing of metal parts.

Tips for optimizing metal fabrication processes include investing in advanced machinery that enhances precision and efficiency. Regular maintenance of equipment can prevent unexpected downtime and ensure consistent output quality. Additionally, training staff on the latest fabrication techniques can lead to improved productivity and reduced waste, ultimately contributing to a more efficient manufacturing operation. Leveraging technology such as CNC machines can also streamline processes, enabling faster turnaround times and better accuracy in creating complex designs.

Importance of Precision in Metal Cutting Techniques and Their Impact

Precision in metal cutting techniques plays a crucial role in enhancing manufacturing efficiency and product quality. Accurate cuts not only minimize material waste but also ensure that assembled components fit perfectly, reducing the need for additional rework. By employing advanced cutting methods such as laser cutting, water jet cutting, and CNC machining, manufacturers can achieve high levels of accuracy that meet stringent industry standards. This precision is vital in sectors such as aerospace, automotive, and medical device manufacturing, where even minor deviations can lead to significant safety and performance issues.

Tips: To ensure precision in your metal cutting processes, consider investing in high-quality cutting tools and machinery. Regular maintenance and calibration of your equipment are essential to maintain cutting accuracy. Additionally, utilizing CAD software can help in creating detailed designs that facilitate precise cuts.

Incorporating automation and computer-numerical control (CNC) systems can significantly enhance the consistency and precision of the cutting process. These technologies reduce the possibility of human error and improve production speed, making it easier to accommodate complex geometries and tight tolerances. As the industry continues to evolve, staying updated with the latest advancements in metal cutting technology will be essential for maintaining a competitive edge in manufacturing.

Tips: Always ensure that your machine operators are well-trained in the latest cutting techniques and practices. Implementing a robust quality control system can help catch deviations early in the process, ensuring that only products meeting the desired specifications go to market.

Advanced Welding Techniques: Enhancing Structural Integrity in Metalwork

Advanced welding techniques play a crucial role in enhancing structural integrity in metalwork. As industries increasingly demand high-performance materials and precise fabrication, innovative welding methods have emerged to meet these challenges. Techniques such as laser welding, electron beam welding, and arc welding are revolutionizing how metal components are joined. Laser welding, for instance, offers minimal heat input, reducing the risk of distortion and ensuring tight tolerances. This precision is particularly valuable in aerospace and automotive applications, where structural integrity is paramount.

Moreover, advanced welding techniques contribute significantly to the improvement of fatigue resistance and overall durability of metal structures. By employing procedures like friction stir welding and gas tungsten arc welding, manufacturers can create stronger welds that exhibit superior mechanical properties. These methods enable the joining of dissimilar metals, which expands the possibilities for design and application. As industries continue to evolve, the adoption of these advanced techniques not only enhances product quality but also increases production efficiency, making them indispensable in modern metal manufacturing.

The Role of Additive Manufacturing in Modern Metal Production

Additive manufacturing, often referred to as 3D printing, is transforming the landscape of metal production, presenting both efficiencies and opportunities for innovation. According to a report by the Wohlers Associates, the metal 3D printing market is projected to grow from $1.1 billion in 2021 to $4.9 billion by 2026, highlighting the rising significance of this technology in the manufacturing sector. This shift is largely due to the capability of additive manufacturing to create complex geometries that traditional subtractive techniques struggle to achieve, enabling the production of lightweight components with less material waste.

One of the standout advantages of additive manufacturing is its ability to produce parts on-demand, significantly reducing lead times. This is particularly crucial in industries such as aerospace and automotive, where design iterations are frequent and rapid prototyping can lead to faster time-to-market. A report by Deloitte suggests that companies adopting additive manufacturing can reduce production costs by up to 80% in some cases, thanks to lower waste and streamlined processes.

Tips: To maximize the benefits of additive manufacturing, companies should invest in training for their engineers and designers to leverage the full potential of this technology. Additionally, collaborating with additive manufacturing specialists can further enhance design and production capabilities, ensuring that the transition from traditional methods is as smooth and efficient as possible. Embracing this modern approach not only fosters innovation but also positions companies competitively in the evolving manufacturing landscape.

Conclusion

The article "Top 10 Metal Manufacturing Techniques for Efficient Production" explores essential methodologies in the metal manufacturing industry, emphasizing their significance in enhancing productivity and precision. It begins with a comprehensive overview of metal fabrication processes, detailing their diverse applications across various sectors. A particular focus is placed on the importance of precision in metal cutting techniques, which directly influences the final product's quality and efficiency.

Additionally, the article delves into advanced welding techniques that contribute to the structural integrity of metalwork, as well as the growing role of additive manufacturing, which is revolutionizing traditional production methods. Innovations in tooling and machining are also discussed, highlighting how they boost efficiency and minimize waste in the manufacturing process. Overall, this comprehensive guide provides valuable insights into the latest trends and technologies in metal manufacturing, making it an essential resource for industry professionals.

Related Posts

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing

-

Top 10 Best Metal Processing Techniques for Efficient Manufacturing

-

How to Choose the Right Metal Coating for Your Projects: A Complete Guide

-

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability

-

Top 10 Benefits of Aluminum Metal Everyone Should Know