Get In Touch

Contact Kelly McNamara for information on products, services or locations.

Recent Posts

- Stamping in an EV World Virtual Conference

- Altair Enlighten Award Webinar Series

- Panel Discussion with Material Sciences Corp and Other 2019 Altair Enlighten Award Winners

- MSC SMART STEEL® FEATURED IN STAMPING JOURNAL

- MATERIAL SCIENCES CORPORATION RINGS THE NASDAQ OPENING BELL

Recent Comments

Archives

- May 2021

- March 2021

- May 2020

- February 2020

- September 2019

- August 2019

- May 2019

- April 2019

- February 2019

- December 2018

- October 2018

- September 2018

- August 2018

- April 2018

- October 2017

- September 2017

- December 2016

- October 2016

- April 2016

- January 2016

- November 2015

- September 2015

- August 2014

- June 2014

- March 2014

- July 2013

- August 2012

Categories

- Automotive

- Burr Ridge

- Canton

- Careers Testimonials

- Elk Grove Village

- Locations

- News

- Product Testimonials

- Products

- Services

- Turin, Italy

- Uncategorized

- Walbridge

Meta

2025 Top Trends in Steel Stamping: Techniques, Industries, and Innovations

In recent years, the steel stamping industry has seen a surge in innovation and growth, driven by advancements in technology and an increasing demand across various sectors. According to a report by Smithers, the global market for steel stamping is projected to reach $50 billion by 2025, highlighting its critical role in industries such as automotive, aerospace, and construction. As manufacturers look to improve efficiency and reduce costs, the adoption of new techniques and materials is becoming imperative.

Industry expert Dr. Emily Chen, a leading figure in metal processing, notes that "the future of steel stamping lies in integrating automation and artificial intelligence to enhance precision and speed." This indicates a pivotal shift towards smarter manufacturing processes that not only boost productivity but also ensure higher quality standards in stamped components. As we look towards 2025, the trends in steel stamping will not only shape the manufacturing landscape but also influence sustainability practices, driving companies to innovate in environmentally friendly methods.

With a keen focus on emerging technologies, innovative techniques, and their applications across various industries, the future landscape of steel stamping holds immense promise. Stakeholders must stay attuned to these trends to remain competitive and leverage the full potential of steel stamping in their operations.

2025 Steel Stamping Market Overview: Trends and Forecasts

The steel stamping market is poised for significant growth in 2025, driven by advancements in technology and increasing demand across various industries. As manufacturing processes evolve, innovations in stamping techniques are enabling greater precision and efficiency. These techniques include progressive die stamping, which enhances production speeds, and advanced materials technology, allowing for the creation of lighter, stronger parts. Such improvements not only reduce waste but also lower costs, making steel stamping an attractive option for manufacturers worldwide.

Key industries fueling the growth of the steel stamping market include automotive, aerospace, and consumer electronics. The automotive sector, in particular, is experiencing a surge in demand for high-strength components that meet both safety standards and efficiency benchmarks. As electric vehicles gain traction, the need for lightweight structural and body parts becomes even more critical. Similarly, the aerospace industry is looking for stamped components that can withstand extreme conditions, pushing the boundaries of traditional stamping capabilities. Overall, the steel stamping market is expected to see a robust trajectory, characterized by a blend of traditional practices and cutting-edge innovations that cater to an ever-evolving industrial landscape.

Innovative Techniques in Steel Stamping: Automation and Robotics

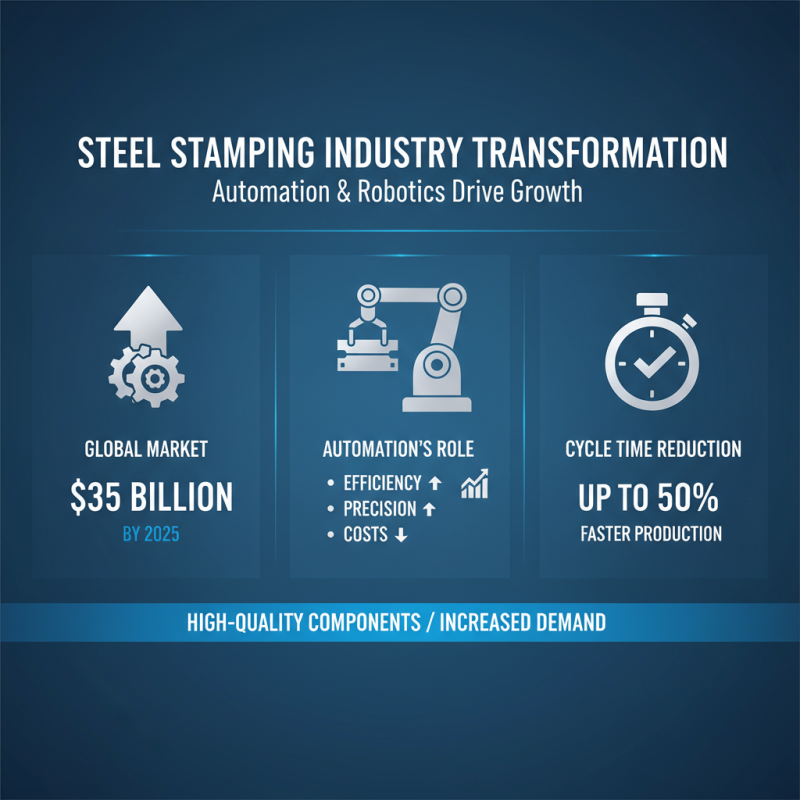

The steel stamping industry is witnessing a significant transformation driven by the implementation of automation and robotics. By 2025, it is projected that the global steel stamping market will reach approximately $35 billion, with automation playing a crucial role in this growth. The integration of automated systems not only enhances production efficiency but also improves precision and reduces operational costs. According to a recent report by a leading industry analysis firm, automated stamping processes can reduce cycle times by up to 50%, enabling manufacturers to meet increasing demand for high-quality stamped components.

Robotic technology is further revolutionizing steel stamping by enhancing flexibility and safety in manufacturing environments. Robots equipped with advanced machine learning capabilities can adapt to various tasks, minimizing downtime and increasing overall productivity. As per the Robotic Industries Association, the adoption of industrial robots in metal stamping is expected to rise by 35% between 2022 and 2025. This trend is particularly evident in sectors such as automotive and aerospace, where the demand for precision-engineered parts continues to surge. As companies embrace these innovative techniques, the ability to streamline production while ensuring quality will position them competitively in the evolving market landscape.

Key Industries Utilizing Steel Stamping: Automotive and Aerospace Insights

The steel stamping industry has witnessed remarkable growth in key sectors, notably automotive and aerospace, highlighting the versatility and importance of metal forming technologies. According to a recent market research report, the automotive sector alone is projected to account for over 40% of the global steel stamping market by 2025, driven by increasing vehicle production and the rising demand for lightweight materials that improve fuel efficiency. This transition towards innovative materials, including high-strength steel, is essential for meeting stringent regulatory standards in emissions and safety.

In aerospace, the demand for precision-engineered components continues to expand. Advanced steel stamping techniques are critical in producing lightweight yet durable parts, contributing to advancements in aircraft design and performance. Reports indicate that the aerospace sector's investments in manufacturing technologies will reach $10 billion by 2025, further underscoring the sector's commitment to innovation, quality, and efficiency.

Tips: When considering advancements in steel stamping, companies should focus on investing in automation technologies to enhance production efficiency. Implementing computer numerical control (CNC) systems can significantly reduce waste and improve accuracy. Additionally, maintaining robust supplier relationships can ensure a steady flow of high-quality materials, which is crucial for meeting the demanding standards of both the automotive and aerospace industries.

Sustainability in Steel Stamping: Eco-Friendly Practices and Materials

The steel stamping industry is witnessing a transformative shift toward sustainability, driven by increasing regulatory pressures and market demands for eco-friendly practices. According to a recent report from the Steel Institute, the implementation of sustainable practices in steel stamping can reduce energy consumption by up to 30%, significantly lowering the carbon footprint associated with manufacturing processes. Innovative techniques such as advanced die design and automated stamping processes not only enhance efficiency but also promote the use of recycled materials, which have shown to decrease raw material costs by approximately 20%.

Moreover, the adoption of greener materials is gaining traction. Research from the International Steel Association highlights that the incorporation of biocompatible coatings and water-based lubricants in steel stamping not only minimizes harmful emissions but also improves the recyclability of the stamped products. The trend toward using low-impact materials aligns with the growing consumer preference for sustainable products, strengthening the case for companies to re-evaluate their manufacturing practices. As the industry progresses toward 2025, these eco-friendly innovations are expected to set new benchmarks for sustainability in steel stamping, ultimately fostering a more responsible manufacturing landscape.

2025 Top Trends in Steel Stamping: Techniques, Industries, and Innovations - Sustainability in Steel Stamping: Eco-Friendly Practices and Materials

| Trend | Technique | Industry | Eco-Friendly Material | Sustainability Practice |

|---|---|---|---|---|

| Advanced Automation | Robotic Stamping | Automotive | Recycled Steel | Zero Waste Production |

| Lightweight Design | Precision Stamping | Electronics | Biodegradable Materials | Energy-efficient Processes |

| Digital Transformation | Smart Manufacturing | Aerospace | Hybrid Materials | Life Cycle Assessment |

| Customized Solutions | 3D Stamping | Construction | Tool Steel | Sourcing from Renewable Resources |

Emerging Technologies: The Role of AI and IoT in Steel Stamping Operations

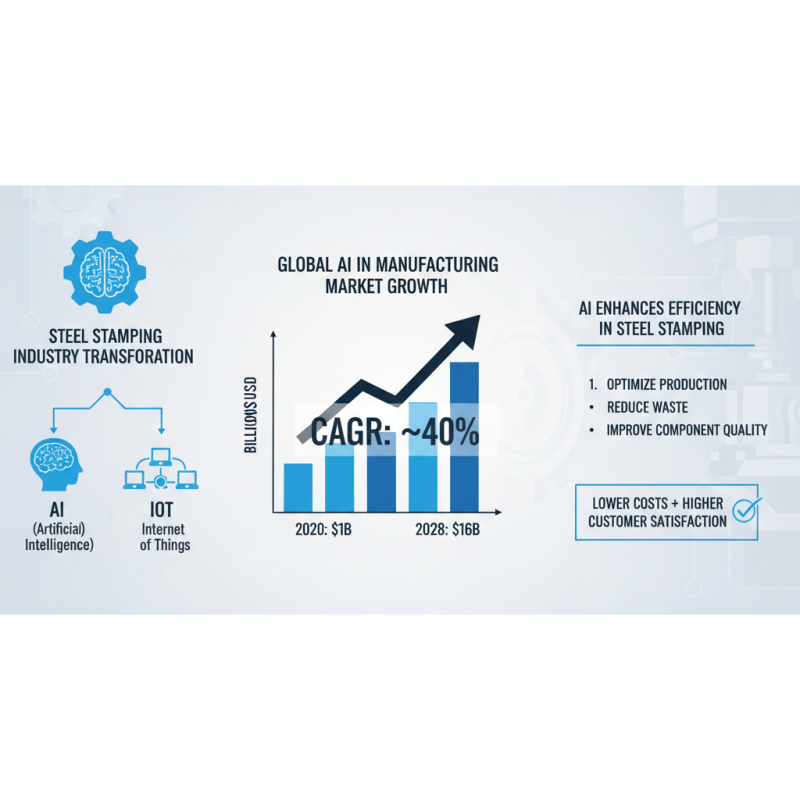

The steel stamping industry is undergoing a significant transformation, driven by the integration of emerging technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT). According to a recent market report, the global AI in manufacturing market size was valued at approximately $1 billion in 2020 and is projected to reach $16 billion by 2028, growing at a CAGR of around 40%. This rapid growth underscores the critical role that AI will play in enhancing operational efficiency within steel stamping processes. By leveraging AI algorithms, manufacturers can optimize production schedules, reduce waste, and improve the quality of stamped components, resulting in lower costs and higher customer satisfaction.

Similarly, the incorporation of IoT devices into steel stamping operations facilitates unprecedented levels of connectivity and data monitoring. With the ability to gather real-time data from machinery and equipment, manufacturers can gain insights into machine performance and maintenance needs, leading to predictive maintenance strategies. A survey conducted by the IoT Analytics revealed that nearly 85% of manufacturing companies are already implementing IoT initiatives to enhance their operational capabilities. Such advancements not only streamline processes but also contribute to better resource management and sustainability, as data-driven insights enable companies to minimize energy consumption and optimize material use.

The synergy between AI and IoT in steel stamping operations heralds a new era of efficiency and innovation. As these technologies evolve, their integration is expected to drive productivity gains, support the development of customized stamping solutions, and secure competitive advantages in a rapidly changing market landscape.

Related Posts

-

Ultimate Guide to Coil Coating Tips for Superior Finish and Durability

-

Top 10 Essential Metals and Materials for Your Next Project

-

10 Essential Tips for Choosing the Right Steel Material for Your Project

-

How to Improve Efficiency in Metal Manufacturing Processes in 2025

-

How to Build a Metal Frame Building: A Step-by-Step Guide for Beginners

-

2025 Top 5 Metal Materials: Innovations Shaping the Future of Manufacturing